If the Eiffel tower had been built 124 years later, Oerlikon would have assuredly played a significant part in its construction. Because what was riveted, screwed or welded together using iron and steel components back then would today be primarily made of composites – and the Oerlikon Textile, Vacuum and Coating segments today supply a wide range of technology and components for their production. These are the focus areas of research at the Oerlikon.

Carbon fibres are used in applications where low weight and extreme stability are prerequisites. Carbon fibre-reinforced plastics are used, to name a few areas, in the aeronautics and aerospace industry, wind power plants, automotive industry, safety technology and in high-quality sports equipment such as racing bicycles, tennis racquets, skis and boats.

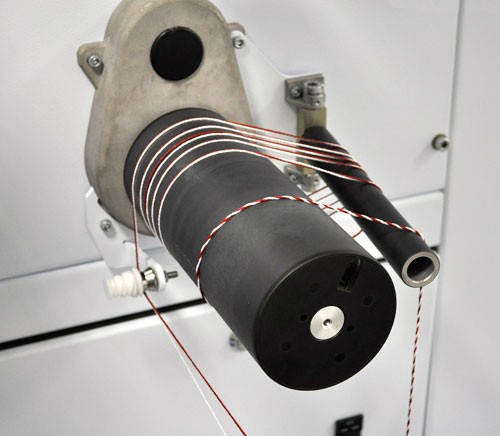

Oerlikon Barmag has developed a winder specially for the production of carbon fibres called WinTrax. The two-yarn winding head combines the economic production of top quality carbon fibres with simultaneously perfect package building and identical running lengths. In addition, the new WinTrax-A 2cop produces packages with a diameter of up to 310 mm. The resulting higher package weights reduce tooling times and therefore significantly reduce outlay during composite production. Due to the identical running lengths of all packages, waste is reduced to nearly zero percent.

Oerlikon Barmag has developed a winder specially for the production of carbon fibres called WinTrax. The two-yarn winding head combines the economic production of top quality carbon fibres with simultaneously perfect package building and identical running lengths. In addition, the new WinTrax-A 2cop produces packages with a diameter of up to 310 mm. The resulting higher package weights reduce tooling times and therefore significantly reduce outlay during composite production. Due to the identical running lengths of all packages, waste is reduced to nearly zero percent.

The production of composites frequently requires filaments or tapes with particular properties, such as high tensile strength, low elongation or a high modulus of elasticity. The extrusion systems for producing these high-quality tapes, mono-filaments and multi-filaments are other specialities of Oerlikon Barmag.

The production of composites frequently requires filaments or tapes with particular properties, such as high tensile strength, low elongation or a high modulus of elasticity. The extrusion systems for producing these high-quality tapes, mono-filaments and multi-filaments are other specialities of Oerlikon Barmag.

Another product worth mentioning here is the independent metering unit GM Control, newly developed by Oerlikon Barmag. Oerlikon Barmag is responding here to the demands of numerous users for an easy to use plug-and-play version of its proven GM metering pump series. The unit can be controlled directly and can also be retrofitted to existing process control systems.

Whether for casting PUR parts, lamination of composite parts, metering additives in an ongoing extrusion process, application of cold adhesives or for flexible use in production systems with changing requirements – the compact and mobile GM Control unit can support all these tasks with the usual high metering accuracy and with even more ease of use.

Whether for casting PUR parts, lamination of composite parts, metering additives in an ongoing extrusion process, application of cold adhesives or for flexible use in production systems with changing requirements – the compact and mobile GM Control unit can support all these tasks with the usual high metering accuracy and with even more ease of use.

The core of the GM Control metering unit – the GM pump – is available for numerous conveying capacities. This means that an appropriate metering unit can be provided for various throughput volumes.

Delicate handling of glass filaments thanks to modern technology

Two further brands in the Oerlikon Textile segment are also presenting their latest products in the glass sector: Oerlikon Saurer and Oerlikon Textile Components. At the Oerlikon joint booth, visitors can learn all about the Volkmann GT (Glass Twister), the trend-setting ring twister used for the production of glass filament yarns. Oerlikon Sauer offers its customers the complete spectrum of innovative solutions and services in the glass sector with its product line Volkmann. The GlassTwister is modular in design and the main components are the creel baskets and ring twisting spindles. Both components are equipped with single motor drives and pneumatic brakes. They are supplemented by the central ring rail drive with servo motor. The complete synchronization of all components and the programmable ring rail guide enables an optimal package build and thereby a perfect processing of the twist packages in the subsequent processing steps. The ergonomic design enables the operating personnel to carefully feed the machine at a comfortable working height, which ensures a careful handling of the spinning cakes and thereby the quality of the feed material.

Two further brands in the Oerlikon Textile segment are also presenting their latest products in the glass sector: Oerlikon Saurer and Oerlikon Textile Components. At the Oerlikon joint booth, visitors can learn all about the Volkmann GT (Glass Twister), the trend-setting ring twister used for the production of glass filament yarns. Oerlikon Sauer offers its customers the complete spectrum of innovative solutions and services in the glass sector with its product line Volkmann. The GlassTwister is modular in design and the main components are the creel baskets and ring twisting spindles. Both components are equipped with single motor drives and pneumatic brakes. They are supplemented by the central ring rail drive with servo motor. The complete synchronization of all components and the programmable ring rail guide enables an optimal package build and thereby a perfect processing of the twist packages in the subsequent processing steps. The ergonomic design enables the operating personnel to carefully feed the machine at a comfortable working height, which ensures a careful handling of the spinning cakes and thereby the quality of the feed material.

Ring Twisting Machine Volkmann GT (GlassTwister)

Twisting of single and multiply yarns : Innovative high-performance ring twisting machine for up-twisting and twisting of glass filament yarns.

The Volkmann GlassTwister is able to twist plied yarn structures, e.g. 3-ply yarns and hybrid yarns, when being equipped with a package creel and godet supply units in place of the creel baskets. Production of single or multi-ply yarns from raw materials in the count range between 10 and 5000 tex. Flexible application areas: e.g. PA, PES, CV, Aramid, PVA, Dyneema, PE/PP as multiple or monofilaments. Oerlikon Textile Components can look back at over 40 years of experience in the production of components specially developed for the glass fibre industry. Oerlikon also offers innovative aprons from the Accotex® series which are used in glass fibre processing. The glass fibre apron Accotex® 964 FG3 was specially developed for super-fine filaments such as BC (4µm)/C (4.5µm)/D (5µm).

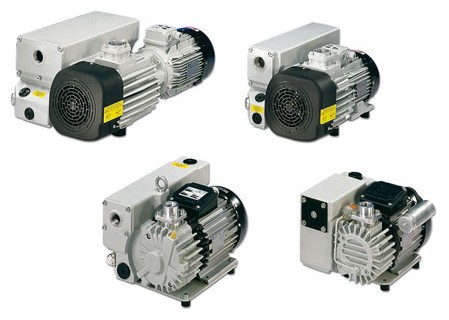

Vacuum pumps are essential in the production of composites

Oerlikon Group’s Oerlikon Balzers offers new coating solutions and Oerlikon Leybold provides the vacuum technology. Oerlikon Leybold Vacuum provides pumps & systems for various applications. The Sogevac, Trivac & SP pump series have proven themselves over the years in degassing, lamination and resin transfer moulding applications. Based on their experience in these difficult processes, Oerlikon Leybold Vacuum can offer optimised vacuum pumps, ranging from 10 to 300 m3/h, and complete systems. The wide motor range enables worldwide deployment of these pumps. Oil-lubricated pumps (Sogevac or Trivac) or dry-running pumps (SP) can be used according to customer requirements. Thanks to specially selected oils, the Trivac & Sogevac series enable long working intervals without maintenance and with adapted optimal performance features. Major manufacturers of wind generator rotor blades, shipyards, aircraft builders and component manufacturers in America, Europe and Asia trust in technology made by Oerlikon Leybold Vacuum.

Oerlikon Group’s Oerlikon Balzers offers new coating solutions and Oerlikon Leybold provides the vacuum technology. Oerlikon Leybold Vacuum provides pumps & systems for various applications. The Sogevac, Trivac & SP pump series have proven themselves over the years in degassing, lamination and resin transfer moulding applications. Based on their experience in these difficult processes, Oerlikon Leybold Vacuum can offer optimised vacuum pumps, ranging from 10 to 300 m3/h, and complete systems. The wide motor range enables worldwide deployment of these pumps. Oil-lubricated pumps (Sogevac or Trivac) or dry-running pumps (SP) can be used according to customer requirements. Thanks to specially selected oils, the Trivac & Sogevac series enable long working intervals without maintenance and with adapted optimal performance features. Major manufacturers of wind generator rotor blades, shipyards, aircraft builders and component manufacturers in America, Europe and Asia trust in technology made by Oerlikon Leybold Vacuum.

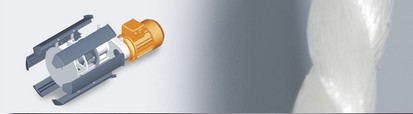

More than 90 Oerlikon Balzers Coating Center worldwide

With almost 90 coating centres in more than 30 countries Oerlikon Balzers offers its customers a globally unique sales, service and after sales network.

Oerlikon Balzers is the world’s leading supplier of surface technologies, which significantly improve the performance and durability of precision components as well as tools for the metal and plastics processing industries. These coatings, marketed under the BALINIT® brand name, are extremely thin and exceptionally hard. They significantly reduce friction and wear. BALINIT® DIAMOND PLUS is the solution for aluminium alloys and composite materials. An especially smooth, nanocrystalline structure facilitates chip flow and prevents the formation of built-up edges. Cutting forces are significantly reduced. Due to the excellent surface quality of the workpieces, no reworking is necessary.