Flooring manufacturers around the globe are responding in more ways than one to keep up with the move by the industry to reduce its environmental footprint.

A leading European manufacturer of high quality, durable carpets and carpet tiles for commercial applications, Desso can look back on over 80 years experience for producing quality flooring for all types of applications. Desso is also a leading carpet supplier to the airframe manufacturers and to numerous airlines around the world, including Boeing, Airbus, Embraer and Bombardier, and airlines like China Airlines, KLM, Norwegian Air Shuttle, Vietnam Airlines and TUIfly. In early 2008, Netherlands-based Desso made a natural decision to take an alternative route and go a step beyond mere sustainability in the company’s design and production, by using their ‘Cradle to Cradle’ strategy.

“Our innovative agenda positively improves the quality of life and the environment, by encouraging our clients to maximize rather than minimize the footprint we create,” explains Nathan Jansen, Aviation Sales Director at Desso. “Look at it this way: sustainability policies tend to lay down rules to lessen the impact on the environment. However, by taking our inspiration from nature’s continuous cycles, we are able to design and create materials to be used as ‘nutrients’ for biological or industrial systems.”

Desso can look back on almost 80 years of experience for producing quality flooring for

all types of applications

Lightweight carpet

Desso’s latest development is the new lightweight carpet; a revolutionary product with a maximum weight reduction of over 40% compared to market standards. The Stratos Fuelmaster is a Wilton woven nylon carpet with a weight of 1100 grams per square meter or 33 oz per square yard. This is 350 to 800 grams less than conventional nylon carpet. The new product is made with sustainable and eco-friendly yarn and offers exceptional value for money without compromising on technical performance. Desso’s R&D team was able to develop a yarn – consisting of BCF polyamide 6 and econyl (which is made of 100% recycled content) fibres – that performs well in terms of all critical criteria, such as durability, staining and shrinkage. The new lightweight carpet is available in 36 colors.

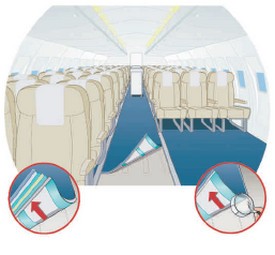

Self-adhesive carpet

For easier handling and installation, Desso has developed self-adhesive carpet. This eliminates the need for tape, enabling not only easier and faster installation, but also faster removal without leaving any residue on the floor. Initially developed for the Boeing 787 Dreamliner, the new self-adhesive carpet made Desso one of the few officially approved suppliers for this type of aircraft. Further development resulted in the option to apply self-adhesive backing to any aviation carpet available at Desso, meaning that it is available for nylon, wool and a blend of 80% wool and 20% nylon, with unlimited design possibilities!

In signing a partnership agreement with the Hamburgbased Environmental Protection Encouragement Agency (EPEA), Desso has become the first carpet manufacturer in EMEA to adopt the ‘Cradle to Cradle®’ design, which involves creating continuous cycles of both biological and technical ‘nutrients’. This means that products are made from positively defined materials that are easy to disassemble, in order to create new products in both the biological and technical cycles. The products have also been produced using manufacturing processes that rely on renewable energy, and seek to conserve water, and to embrace social responsibility.

“Our Cradle to Cradle® strategy goes beyond sustainability and definitely sets us apart from our competition. Whereas our competition tries to minimize the negative impact on our planet, we aim to set a positive footprint. Doing it right, rather than ‘less bad,’” Jansen said.

Desso also developed an innovative separation technique called Refinity,® that involves separating the yarn and other fibers from the backing. The separation produces two main material streams that can be recycled. After an additional purification stage, the yarn is returned to the manufacturer for the production of new yarn (some virgin material is needed to compensate for losses and ineffciency process). To top it off, one of Desso’s yarn suppliers, Aquafil, has developed proprietary technology at its regeneration plant to turn recovered post-consumer Polyamide 6 carpet fibres into new Polyamide 6 again and again.

Furthermore, Desso also supports the Carpet Take Back Programme™ at Schiphol Airport, in cooperation with KLM Royal Dutch Airlines.

“The carpets in KLM’s airplanes are being replaced every five to six months, resulting in 35,000 square meters of carpet waste on a yearly basis. Rather than discharging this to traditional waste incineration, 80% of the waste (which equals 28,000 square meters of carpet) is taken back from Schiphol Airport and used as secondary fuel for the cement industry,” Jansen said. KLM and Desso are planning to expand the Carpet TakeBack Programme™ to Transavia and other companies within the KLM Group. “At the same time we are also continuously taking steps forward in the development of a Cradle to Cradle carpet for airplanes as well. We are progressing toward a 100% Cradle to Cradle® strategy in 2020,” Jansen added.

To many people outside the industry, flooring within an aircraft may seem like a relatively simple element of a cabin’s interior. However, behind the colour, fabric and design are important considerations made towards sustainability within the manufacturing process – choices which have the power to affect a company’s social, financial and environmental objectives to a great extent.

Light as a feather

Another company aware of environmental pressures is Gerflor, which is based in France and has been manufacturing aircraft flooring since 1948. “We are recognized as a specialist and a world leader in resilient flooring solutions. Our company creates, manufactures and markets innovative, design-led and eco-responsible solutions for flooring and complementary interior finishes,” said Mélina Plassart, Aviation Product Manager at Gerflor. Gerflor developed what it says is the world’s lightest non-textile floor covering, called, Batiflex AV135. All Batiflex floor coverings offer superior anti-slip properties, dimensional stability, durability, ease of installation, cleaning and maintenance. “Qualified and selected as a standard baseline for the Boeing 787 program, the Batiflex AV 135 helps provide competitiveness and success to our customers – which include Air India, All Nippon Airlines, China Southern, Japan Airlines, Qatar Airways, Hainan Airlines, LOT Polish Airlines and more, “ she said. According to Plassart, all of Gerflor’s products are developed with the intention to optimize the environmental impact at every stage of the product’s life, this is what the company calls, “from cradle to grave.” This process includes assessment of the manufacturing, installation, ongoing maintenance and recycling of the products as well.

Gerflor’s manufacturing facilities are ISO 14001 certified and the company only selects raw materials that contain no heavy metals, carcinogenic, mutagenic or reprotoxic components. When it comes to upcoming trends and predictions for the flooring sector within the aviation sector, Plassart told PAX International that wooden or decorative patterns will increase in popularity over time, and will definitely develop within the next few years. “This trend is noticeable at OEMs and in the retrofit market. Some regions of the world nevertheless remain quite conservative compared to others.”

Unique tape technology

Based in Bavaria, Germany, and now part of the Planatol Group of companies, BIOLINK was started by three chemists who were interested in what adhesive tape technology could compete with, based on a technical and performance level, but which could be far kinder and friendlier to the environment. It was 15 years ago that BIOLINK developed their proprietary 100% acrylic, solvent free, UV cured technology, and to this day it is the only company that produces its entire product range using this specific technology.

Biolink Tape Solutions, a leading supplier of pressure-sensitive adhesive tapes, films and foils, offers aero flooring solutions. Biolink’s proprietary, solvent-free adhesive technology is used to produce a wide variety of high performance adhesive tape solutions, for many industries and critical applications, such as aircraft flooring.

The ‘relink 2318’ Airbus approved and specified carpet tape, continues to build sales among leading airlines and MRO companies around the world. This tape enables quick installation, secure lift-free fixation across all carpet backing types and rapid residue- and damage-free removal, in one piece. These benefits translate into quantifiable cost savings for the customer.

Biolink has also introduced several new products currently in qualification, including transfer adhesives for safety labels, NTF tape and a new carpet tape, designed to provide increased adhesion to the floor, whilst still providing clean peel, residue and damage-free removal.

BIOLINK’s unique technology is based on one fundamental environmental principle: to produce and coat adhesives without chemicals that would harm the environment or employees. “We believe that every business has the responsibility to take care of the environment in a sustainable manner in every one of its production processes. We pursue this important principle, delivering our promise to take care of future generations while at the same time combining it with commercial interests,” said Andrew Jenner, Business Development Manager at BIOLINK.

“BIOLINK is happy to be ISO 14001 accredited, but for us, this is only the start. We will not use chemical components in our production that could be harmful for our employees, customers or the environment. Our technology only uses relatively small amounts of energy, no drinking quality water and we do not exhaust any by product into the air or the public water system,” Jenner told PAX International. BIOLINK has customers around the world, primarily in aerospace, automotive, and electronics industries and are highly regarded in the marketplace, for providing creative ideas for fixing, bonding and mounting challenges. “We remain very proud of the development work we did with AIRBUS, to design a new carpet tape (Relink 2318). This was very much a joint project, specifically to solve the problems associated with the more mature products in the market, such as residue upon removal, composite damage, residue removal by solvent and scraper, all of which cost significant time and money.” Relink 2318 remains the only carpet tape product used by Airbus and due to this good working relationship, BIOLINK and Airbus now have several other projects with tape products in progress. (Courtesy : Lauren Brunetti, Pax International)