Nano-particles (Greek: nanos = dwarf) are now being used to create fascinating products with totally new functionalities. These include textiles from which dirt simply runs off or which have an anti-bacterial effect. But as is the case with every new technology, this one must also be safe to use. It is therefore of interest to both manufacturers and users of such high-tech products that nano-particles are harmless for both human beings and the environment over the entire life cycle of the products.To this end in December 2010 the “TechnoTox” research project was launched with the objective of performing a situation-based risk assessment of textile nano-products. The project is sponsored by the German state of Baden-Württemberg and is based on an initiative of AFBW e.V. (Allianz Faserbasierte Werkstoffe Baden-Württemberg) and is studying in detail the questions surrounding textile nano-technology.

The German Council on the Environment (SRU) published the following statement in 2011 on the use of nano-materials: “To date there has been no scientific proof to the effect that nano-materials, as manufactured and used today, lead to damage to the environment and to health.”

However, since an increasing use of nano-functionalised textiles is expected in the future in addition to possible uses of new nano-materials which have not yet been considered in previous risk assessments, there is still a need for meaningful test methods on the effects of nano-materials and their toxicological properties.

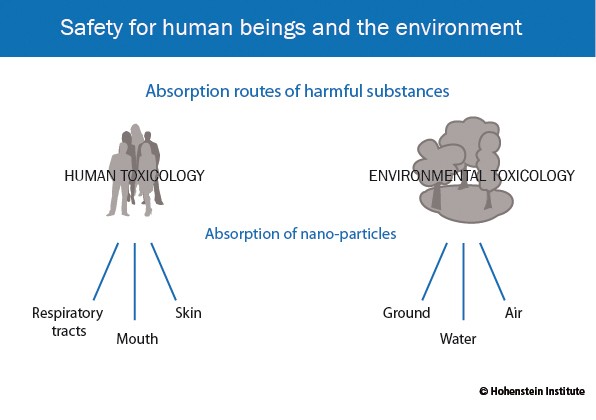

The “TechnoTox” project is studying whether nano-functionalised textiles are safe for human beings and the environment. Data on behaviour, retention and on the biological effect of nano-functionalised fibre-based materials in relation to environmental conditions is being prepared and a situation-based risk assessment is being carried out. During the project methods are also being developed which have made possible the proof and characterisation of nano-particles alongside the analysis of their human and eco-toxicological risk potential in relevant environmental media.

The Hohenstein Lung Model has been used to investigate whether nano-particles can be absorbed from the air that we breathe. © Hohenstein Institute

The project is being run in close cooperation between science and industry. The project partners involved are the Institut für Textil– und Verfahrenstechnik Denkendorf (ITV), the Hohenstein Institute for Textile Innovation and several industrial companies.

Through their participation in the project all participants want to drive forward their own developments in nano-technologically modified textiles and ensure their safety from a risk perspective based on the accompanying and complementary test methodology. An interdisciplinary approach is secured through the involvement of commercial companies. This is being implemented using the example of the textile chain of companies in Baden-Württemberg.

The objective of this project is to expand the competitiveness of the innovative companies which are producing nano-products plus also to process nano-materials or nano-technologically functionalised materials as well as to support the responsible utilisation of nano-technology. The project is using a complementary solutions-based approach in which physical materials studies on exposure are directly coupled to effect-related biological studies. The results of the studies are aggregated and assessed for any correspondence of effects (of the effective concentration for example). The determination of particle properties and effects on real products enables a comprehensive hazard and risk assessment to be made for nano-technology functionalised fibre-based materials in consumer products.

About Hohenstein Institute :

The Hohenstein Institute offers manufacturers, retailers, service providers and consumers “competence from one single source”, covering a wide range of distinct, but closely linked fields of work. The result of this interdisciplinary approach is the successful cooperation with other research institutes from sectors such as medicine, electronics or microsystem technology. These networks open up totally new areas of application for textile products and thus provide the Hohenstein Institute’s clients with additional markets and opportunities for the future.

Contact details :

Hohenstein Laboratories GmbH & Co KG

Schloss Hohenstein

74357 Bönnigheim, Germany

Fon +49 (0)7143 271-723

Fax +49 (0)7143 271-721

Internet : www.hohenstein.de