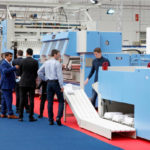

“Industry 4.0” is the new buzzword becoming very fashionable, and hence, considerably over used. Industry 4.0 – also termed as the 4th generation of the industrial revolution – essentially represents the digital transformation of traditional industries like manufacturing to intelligent factories with the advancements in automation, advanced materials, 3D printing, artificial intelligence, augmented reality, cobots (collaborative and robots). Adaptive and ergonomic production lines, intelligent robots and integrated energy systems – all parts of Industrial Internet of Things (IIoT) – are increasingly making it possible for companies to digitize their manufacturing operations. This digital transformation is enabling them to become 24×7 connected intelligent factories. In a nutshell, Industry 4.0 converts your facility into a smart factory by providing it a working brain to impart more advanced built-in intelligence for the factory equipment and products enabling them to work together. Hence, the product will be able to tell the machine – at components level – what to do. The factory equipment runs on very sophisticated software which helps machines self-regulate and make more autonomous and intelligent decisions. The key features of a “Smart’ or “Digital” factory are: self-optimization, self-configuration, self-diagnosis, cognitive and machine learning to significantly increase the efficiency and output while reducing the waste and unnecessary tasks with minimum human intervention. However, the Industry 4.0 may lead to huge displacement of workforce as tiny intelligent robots can replace them for doing the same job more accurately, rapidly and economically.