UK made bio-derived polymers and composites used by Lotus and Citroën

How far have we come with natural fibres? To what extent can bio-derived polymers provide an engineering solution? Following biocomposite demonstrators such as the Lotus Eco Elise and the Eden surfboard which uses a linseed oil-based resin, we are starting to see bio-derived composites compete for mass production industrial applications.

How far have we come with natural fibres? To what extent can bio-derived polymers provide an engineering solution? Following biocomposite demonstrators such as the Lotus Eco Elise and the Eden surfboard which uses a linseed oil-based resin, we are starting to see bio-derived composites compete for mass production industrial applications.

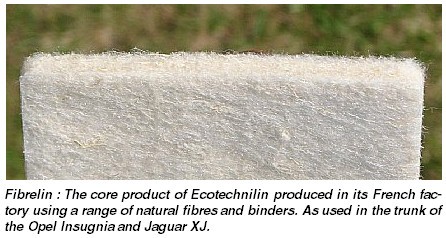

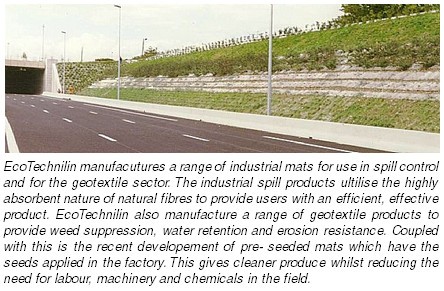

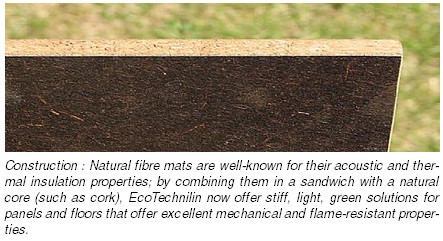

UK-French company Ecotechnilin is producing natural fibre products on a commercial scale. Its non-woven mats of comingled flax with various binder blends are being used in high volume production for the Citroën C4 door panels, and Opel Insignia boot trim panels. It has recently introduced two new products – Fibriboard, a board using 100% flax mat impregnated with bio-resin, and Fibricork, which sandwiches a granulated waste cork core between two sheets of bio-resin-impregnated flax mat.

Ecotechnilin’s facilities include 2 non-woven mat production plants and an R&D facility. In Northern France, their factory uses a carding and cross-lapping process to form the mats; they are then consolidated using a needlepunch process. In the UK near Cambridge the company’s facility forms the mats using its Patented Airlay process; the mats contain a bi-component binder and are consolidated in an oven.

Ecotechnilin’s facilities include 2 non-woven mat production plants and an R&D facility. In Northern France, their factory uses a carding and cross-lapping process to form the mats; they are then consolidated using a needlepunch process. In the UK near Cambridge the company’s facility forms the mats using its Patented Airlay process; the mats contain a bi-component binder and are consolidated in an oven.

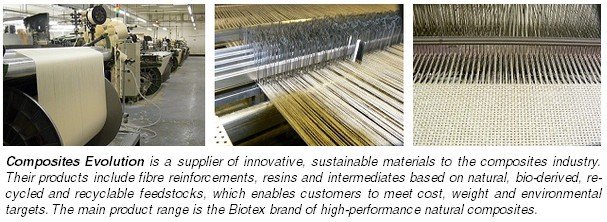

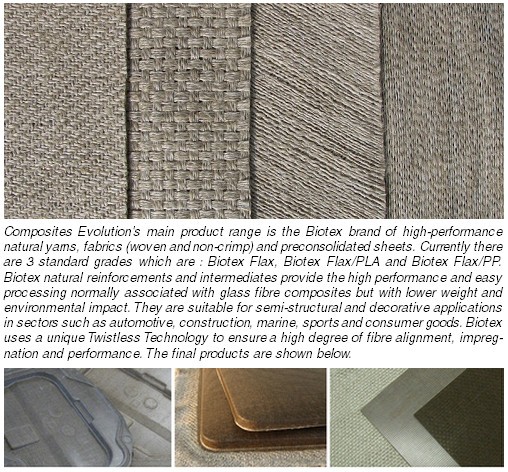

Chesterfield company Composites Evolution markets the Biotex range of more structural woven flax fabrics for those seeking an all-natural product. It also weaves flax fabrics for resin transfer moulding/vacuum infusion with thermoset resins.

Polylactic acid (PLA) is a thermoplastic derived from corn starch or sugars. It is finding acceptance in a range of products, produced by companies such as USA-based Natureworks. Brazilian chemical giant Braskem (see page 67) expects to have a major polyethylene production facility commissioned before the end of 2010, using ethanol from sugar-cane waste as the primary feedstock. Renewable polypropylene production is past pilot stage and should be up and running within a few years.

Polylactic acid (PLA) is a thermoplastic derived from corn starch or sugars. It is finding acceptance in a range of products, produced by companies such as USA-based Natureworks. Brazilian chemical giant Braskem (see page 67) expects to have a major polyethylene production facility commissioned before the end of 2010, using ethanol from sugar-cane waste as the primary feedstock. Renewable polypropylene production is past pilot stage and should be up and running within a few years.

Thermoset composite resins are also forging a path to market. Canadian boat maker Campion Marine recently announced plans to use Envirez, a predominantly bio-derived resin that uses a substantial amount of soybean oil and corn-derived ethanol.

Thermoset composite resins are also forging a path to market. Canadian boat maker Campion Marine recently announced plans to use Envirez, a predominantly bio-derived resin that uses a substantial amount of soybean oil and corn-derived ethanol.

Furan is a thermoset resin derived mainly from sugar cane waste, supplied in Europe by Belgian company TransFuran chemicals. It is reported to have fire resistance properties comparable to phenolic resins. Resins derived from various natural products are working their way up the technology readiness level scale, and work is ongoing in several UK universities.

Furan is a thermoset resin derived mainly from sugar cane waste, supplied in Europe by Belgian company TransFuran chemicals. It is reported to have fire resistance properties comparable to phenolic resins. Resins derived from various natural products are working their way up the technology readiness level scale, and work is ongoing in several UK universities.

Some of this is not new. Tree resins have been used for rubber and as adhesives for centuries. More recently, in the automotive sector natural fibres have been used for decades and many cars now contain natural fibres in their seat structures and parcel shelves. In 1940 car manufacturer Henry Ford used to swing an axe onto his soybean-based plastic trunk lid to demonstrate its strength.

Part of this involves developing a consistent, growing supply of plant resources. Some of the resources for natural resins and polymers can be derived from agricultural waste. Many of the natural fibres can be grown in poor soil, but market drivers should not displace essential food supplies or incentivise the destruction of rainforests.

| Furan : Furan thermosetting bioresins are derived from hemicellulose, which are typically found as waste products from the agricultural industries (typically sugar cane bagasse). The incorporation of flax fibres into the furan system (instead of glass fibres) requires significant modifications to the resin chemistry to make composites with comparable mechanical properties to conventional glass fibre composites. However, these composites involve the use of traditional resin/matrix, the synthesis of which poses the danger of environmental damage. Alternative resins need to be developed in order to reduce the environmental impact of composite production. By using long, aligned natural fibres in conjunction with naturally derived resins, 100% bio-based composites with improved mechanical properties can be achieved and can potentially be employed for more structural purposes. A natural fibre/furan prepreg system has already been successfully developed and used to replace glass fibre. Considering the high specific stiffness of bast fibres such as hemp and flax compared with glass, there is a strong argument technically, as well as environmentally, for the use of such materials in light weight composites. Furan bio-resin has attracted interest for use in composite materials for high performance applications. Sustainability has recently become a key issue pushing up the use of natural fibre reinforced composites sharply. |

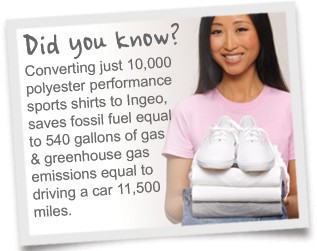

Since Ingeo was introduced in 2003, NatureWorks LLC has been dedicated to driving environmental progress through developing the global market for bio-based plastics & fibers. As with many new technologies, there is a real need to clarify some facts about how Ingeo is made and what makes it different from the oil-based plastics & fibers Ingeo is replacing today. Ingeo is made from dextrose (sugar) that is derived from field corn already grown for many industrial & functional end-uses. In North America, corn has been used first because it is the most economically feasible source of plant starches. NatureWorks use less than 1/20th of 1% (0.05%) of the annual global corn crop today, so there’s little to no impact on food prices or supply. The process does not require corn, we only need a sugar source. This could include sugar beets, sugar cane, wheat and more. In the future… Ingeo will be made from cellulosic raw materials, agricultural wastes and non-food plants.

Since Ingeo was introduced in 2003, NatureWorks LLC has been dedicated to driving environmental progress through developing the global market for bio-based plastics & fibers. As with many new technologies, there is a real need to clarify some facts about how Ingeo is made and what makes it different from the oil-based plastics & fibers Ingeo is replacing today. Ingeo is made from dextrose (sugar) that is derived from field corn already grown for many industrial & functional end-uses. In North America, corn has been used first because it is the most economically feasible source of plant starches. NatureWorks use less than 1/20th of 1% (0.05%) of the annual global corn crop today, so there’s little to no impact on food prices or supply. The process does not require corn, we only need a sugar source. This could include sugar beets, sugar cane, wheat and more. In the future… Ingeo will be made from cellulosic raw materials, agricultural wastes and non-food plants.

Ingeo fiber can look like natural cotton or even lustrous techno-performance wear. This natural versatility means the apparel is both beautiful & eco-conscientious since it’s made from Ingeo fiber. Because Ingeo is made from plants, not oil, creating this apparel uses 50% less non-renewable energy & results in 60% less greenhouse gases. Choosing apparel made from Ingeo fiber is a step in the right direction, an ingenious way to make a small change for the better. You can help change the world, even it’s just one t-shirt at a time.

Eco-friendly benefits of Ingeo fiber :

Eco-friendly benefits of Ingeo fiber :

1. Outstanding moisture management properties

2. Outperforms PET fabrics for breathability, comfort & insulation

3. Better UV performance than other synthetics

4. Easy care, quick-dry & no need to iron

5. Hypoallergenic showing no evidence of skin sensitization

6. Natural resistance to staining

7. Low odor retention