Leader in the production of machines for baby diapers, incontinence products, lady sanitary napkins, bed underpads, fluid absorbing pads, and bibs for babies and adults.

Cellulose Converting Solutions (CCS) is an Italian company working in the field of engineering and installation of complete lines for disposable hygienic products manufacturing. The company founded by the merger of a leading investor and two groups of technicians and designers with thirty-year experience in the production of machines for baby diapers, incontinence products, lady sanitary napkins, bed underpads, fluid absorbing pads, and bibs for babies and adults. The company achieved many international goals thanks to its skill in this field, joined to a continuous desire of innovation and technological development.

Cellulose Converting Solutions (CCS) is an Italian company working in the field of engineering and installation of complete lines for disposable hygienic products manufacturing. The company founded by the merger of a leading investor and two groups of technicians and designers with thirty-year experience in the production of machines for baby diapers, incontinence products, lady sanitary napkins, bed underpads, fluid absorbing pads, and bibs for babies and adults. The company achieved many international goals thanks to its skill in this field, joined to a continuous desire of innovation and technological development.

The company extends over an area of 65.000 sqm of which 17.750 sqm indoor, of these 750 are assigned to the mechanical and electrical design department and 250sqm to workshops. Only this leads to reason on the importance that CCS gives to creative and innovation processes. The engineering department, in which permanently work about 20 skilled engineers, is supported by the most advanced technologies of the field that allows creating equipment upon request that satisfies the specific needs of each partner. For the spare parts, at last, a warehouse of 2500 sqm.

CCS at present employs about 70 persons, each strong of its substantial experience acquired. This guarantees maintaining the high level professional standards and a continuity in the business relationships already consolidated by the company. CCS now is appearing on the related market proposing a complete range of production lines with high technological content satisfying the following areas :

1. sanitary napkins lines. 2. panty shield lines. 3. light incontinence lines. 4. pull on type diapers lines. 5. baby diaper lines. 6. incontinence lines. 7. fluid absorbing pads lines. 8. underpads lines. 9. bibs lines. 10. milk-breast cups lines.

Disposable baby diaper mfg. machine : Model CCS.ND-sky Production Speed : 700 pieces/min. (according to the size)

The company stands out on the market as leader for the engineering & manufacturing of :

1. textile backsheet lamination 2. diapers individual wrapping equipment 3. sanitary napkins individual wrapping equipment and panty shields with “easy wrap” method4. fluff pads drum forming equipment for diapers and sanitary napkins machines

5. “side panels” realization and application equipment for diapers and incontinence products 6. trims compacting unit

Disposable lady sanitary napkin mfg. machine : Model CCS.AN-sky Production Speed : over 1200 pieces/min. (according to the size)

CCS ensures a careful inspection of all types of materials, implementing procedures that achieve high level standards. Moreover the company is involved in the continuous compliance of ISO 9001 standards in every process stage. The strictness with which the machines are qualified and accepted translates in their high reliability, central element in the loyalty relationship that CCS has with its own partners.

——————————————————————————————————————–

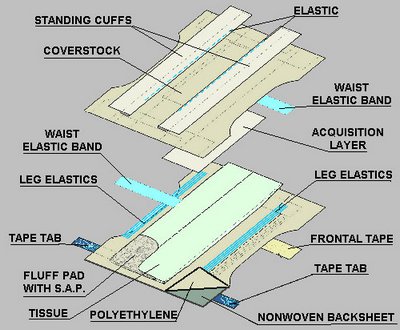

Baby diaper with Textile backsheet feature

Textile backsheet unwinders in two different configurations

Textile backsheet unwinders in two different configurations

This machine unwinds the polyethylene backsheet material and the nonwoven web and joins them together. The material obtained is a cloth-like backsheet to be further coupled to other raw materials on the baby diaper production machine. The key features are :

1. Thermo sealing station or glue with s-wrap roller to couple the raw materials

2. Completely servo-driven or power supplied by alternate current

3. Machine direction from right to left or vice versa

——————————————————————————————————————–

Services Offered :

1. CCS ensures a very high after-sales service level.

2. A team of specialized technicians can provide prompt service within a few hours anywhere the world from the moment of the request.

3. A dedicated spare parts division can supply customers with information, suggestions, quotations, and shipment of any spare part.

4. What more CCS supplies to customers complete and detailed isometric drawings, in order to facilitate direct maintenance on machines and training programs for machine operators and maintenance staff.

5. At last, a teleassistance service enables to analyze and intervene, via computer, on the PLC at the client’s site directly from CCS’s electronic department.

Contact details :

Cellulose Converting Solutions S.p.A.

Viale Kennedy, 40,

C.da Valle Del Molino,

65010 Moscufo (PE) Italy