Introduction :

Nanotechnology is increasingly seen as a wonder for creating new, innovative and high-performance products. Over the last ten years, applications of nanotechnologies have grown and can be found in textiles, food packaging, cosmetics, sports equipment and more. Global research is being carried out to capture and commercialize nanotechnology for new and enhanced products, today and for the future. Nanotechnology applied to textiles is providing opportunities for innovation through novel product features, improvements in production methods and energy savings. Every major textile producing country is moving forward with nanotech textiles to participate in the ongoing research, in order to excel where value is added to textile materials and products. An overview of promising nanomaterials and nanotechnology applications is presented here and industry challenges in developing and applying nanotechnology are described.What Is Nano?

The definition of nanotechnology, developed by Technical Committee 229 of the International Organization for Standardization (ISO), is as follows: “The application of scientific knowledge to manipulate and control matter in the

nanoscale (i.e., size range from approximately 1 nm to 100 nm) to make use of size- and structure-dependent properties and phenomena distinct from those associated with individual atoms or molecules or with bulk materials”

One nanometer (nm) is one billionth of a meter, larger than an atom, but still very small. At this scale, new, size-related properties and phenomena can emerge which, in turn, may offer novel characteristics enabling development of new products.

In October 2011, Health Canada, one of Canada’s regulatory agencies, was one of the first in the world to establish a working description of nanomaterials:

“Health Canada considers any manufactured substance or product and any component material, ingredient, device, or structure to be nanomaterial if: It is at or within the nanoscale (1 to 100 nanometers inclusive) in at least one external dimension, or has internal or surface structure at the nanoscale, or; It is smaller or larger than the nanoscale in all dimensions and exhibits one or more nanoscale properties/phenomena, i.e. properties which are attributable to size and their effects; these properties are distinguishable from the chemical or physical properties of individual atoms, individual molecules and bulk material.”

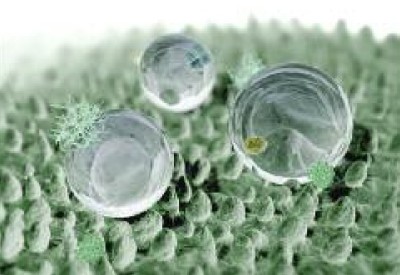

In general, nanotechnologies are inspired by nature that shapes itself “atom by atom.” Through special manipulation and careful size control of common materials like carbon, gold, and silver, characteristics are realized, not demonstrated by their bulk material counterparts. It may impart new properties to fibres and fabrics, and may also be used to improve existing properties. For example, some of the textiles now being developed model the lotus leaf surface to improve their stain resistance. The source of this special behaviour of nanomaterials at the nanoscale has been attributed in part to the much larger surface area of nano-objects as revealed by modern electron microscopy. This was a breakthrough event for nanotech-nologies.

Extensive Potential – Some Examples of Applications in the Textile Industry

Among the most interesting nanotechnology applications for the textile industry are those which offer the possibility of reducing the use of harsh chemicals (such as in antimicrobial applications), improve the long-term performance and durability of textiles, generate products which are more eco-friendly and “greener”, as well as applications which deliver performance-enhancing features and greater durability.

Several promising nanotechnology applications :

Fig. 3 : A computer model representation of self-cleaning or the “lotus effect”. The nanostructured surface of lotus plant leaves cause a high contact angle between the water droplet and plant surface. This repels the water and, as it rolls across the leaf, it picks up dirt and contaminants which also have low surface contact affinity.

- Although not yet ready for industrial-scale use, carbon nanotubes are considered to be particularly promising for the industry, given their ability to strengthen fabrics and textile coatings, without adding significant additional weight

- Antimicrobial and antibacterial applications are highlighted as representing important potential opportunities enabled by nanotechnology developments. Typically, these involved silver compounds (copper was mentioned as well)

- Electrospinning of nanofibres is being explored by some companies. Examples of R&D in this area include coating non-woven felts with a layer of nanofibres produced by electrospinning; however, potential applications were not disclosed for confidentiality reasons

- Nanoparticles to test the efficiency of protective textiles and other materials. A few companies indicated that there is a market need for “nano-enabled resistant clothing” for worker protection

- Nanomaterials to reduce the quantity of harmful chemicals in finishing recipes

- Nanomaterials (other than carbon nanotubes) to strengthen fabrics and enhance coatings, for example nanoclays

- Nanocoatings for oil, water, flame and heat resistance

- Use of nanotechnology for biomimics, such as recreating the surface of a lotus leaf on textiles at the nanoscale in order to reproduce its resistance to oil and water, for potential use in self-cleaning textile applications.

———————————————————————————————————— Nanotechnology Use

————————————————————————————————————

Silver nanoparticles Antibacterial

Nanofibers Filtration, higher strength

Electricity-generating fibers (piezoelectric) Electronic clothing ————————————————————————————————————

Need for Education and Training in Nanotechnology for Textiles :

The textile industry workforce is largely unfamiliar with the terms and general domain of nanotechnology and is not well-prepared to work in this area. As an example, workers are not used to thinking and working in nanoscale dimensions.

The chemistry associated with nanotechnology is often different from the chemistry used in textile dyeing or finishing. The industry may not know how to evaluate available nano-materials, devices and nano-enabled products or how to compare their potential performance and added value.

The potential of nanotechnology is vast, and development is at an early stage. The textile industry is looking at breakthrough products in medicine, clothing, protective equipment, transportation, aerospace, and much more. With this, the Canadian textile industry has the potential to improve its competitive edge, where new value is added to textile materials and products.