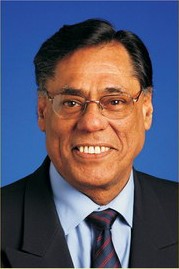

Prof. Subhash Anand

MBE; Comp. Tl; C.Text. FTI

Professor of Technical Textiles,

Institute for Materials Research and Innovation, The University of Bolton, Bolton, UK

Abstract

Technical textiles market worldwide is forecast to grow by 4 per cent per annum between 2002 and 2010. As a result, by 2010 the technical textiles and industrial nonwovens sector will consume some 23.8 million tones of fibre – up from 16.7 million tones in 2000 and a value of US $ 90 billion – and have a value of US $ 126 billion. Knitted fabric production for technical textiles showed on overall growth of 34.5 per cent from 1995 to 2002 in Western Europe. Over the last decade knitted fabrics and products have been increasingly designed and developed for a very wide spectrum of technical applications, including automotive textiles, medical textiles, geotextiles, sportswear, safety and protective textiles and environmental protection textiles, just to name a few major growth areas of technical textiles. Warp and weft knitted spacer materials are being commercially developed for a very wide range of technical textile products, because of a number of unique design opportunities that they offer. Knitted spacer fabrics are a single

composite of at least three different substrates integrated together during the knitting process.The range of materials and structures that are possible are virtually limitless. It is possible to engineer fabrics with specific tailor-made characteristics from 2mm to 60mm in warp knitting and 2mm to 10mm in weft knitting. The paper discusses a number of significant developments in both knitting technology and knitted structures for a range of specific product applications. Warp and weft knitting spacer technologies will be discussed in depth and their present and future potential will be critically analysed. It is hoped to demonstrate that both warp and weft knitting technologies have a significant growth potential in the present and future technical textiles markets worldwide.

About Prof. Subhash Anand

Subhash Anand is Professor of Technical Textiles at the Institute for Materials Research and Innovation (IMRI), The University of Bolton, U.K. His main areas of research activities include; novel knitted and nonwoven structures for technical applications; healthcare and medical devices; effect of laundering on sensory and mechanical properties of textile materials; composite materials; sportswear and activewear structures; filtration; geotextiles; automotive textiles; and personal protective equipment (PPE). He has published over 200 research papers in the above areas of technical textiles and holds six patents. He has organised four International Conferences and Exhibitions in medical and healthcare devices (MEDTEX) at Bolton and has organised three conferences each in Czech Republic and Finland. Todate he has attracted over £2.5 million in grants, sponsorships and industrially sponsored research projects.

He has completed assignments for ODA, UNDP and was Visiting Professor at the Indian Institute of Technology, New Delhi; India in 1984 and 2007 and Institute of Textile Technology, Charlottesville, Virginia, U.S.A. in 1994. He also works as a consultant with UNIDO and has recently completed assignments as an expert in Jute and Technical Textiles in Dhaka and Manila. He works as a consultant with Bhilwara Group India in their automotive textiles company (BMD) and knitting company (Maral Overseas). He was the Chairman of the Board and Council of The Textile Institute from 10th May, 2008 to 10th May, 2010 and was awarded Member of the Order of the British Empire (MBE) for services to the Higher Education and the Textile Industry in January 2008. He was also awarded the Companionship of The Textile Institute (Comp Tl) award in 2011. This is one of the Institute,s most prestigious honours, and is limited to 50 living members.