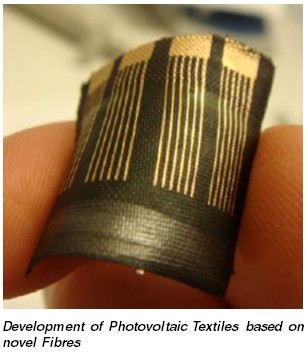

European DEPHOTEX-Project Development of flexible textile solar cells

Deutsches Textilforschungszentrum Nord-West e.V., Krefeld

Solar energy conversion is an object of continuous research, focusing on improving the energy efficiency as well as the structure of photovoltaic cells. With efficiencies continuously increasing, state of the art PV cells offer a good solution to harvest solar energy.

Solar energy conversion is an object of continuous research, focusing on improving the energy efficiency as well as the structure of photovoltaic cells. With efficiencies continuously increasing, state of the art PV cells offer a good solution to harvest solar energy.

However, they are still lacking the flexibility and conformability to integrate them into common objects or clothing. Moreover, many sun-exposed surface areas are textile-based such as garments, tents, truck coverings, boat sails, and home or outdoor textiles.

The research project DEPHOTEX, co-funded by the European Commission (FP7-NMP) and 14 partners from 7 European countries, fills the gap by developing photovoltaic textiles with properties inherent to fabrics: flexibility, low weight, durability, water/dust resistance.

The innovative approach of the work presented here is to build up flexible photovoltaic cells layer by layer taking fabrics as new carrier materials, which is of high scientific and, moreover, commercial relevance.

Activities were focused on the deposition of metallic and non-metallic conductive films on textile materials by different chemical and physical techniques. Finally, we obtained flexible textile-based solar cells with efficiencies in the range of 2 %.

Contact details :

Deutsches Textilforschungszentrum Nord-West e.V., Adlerstr.1, D-47798 Krefeld

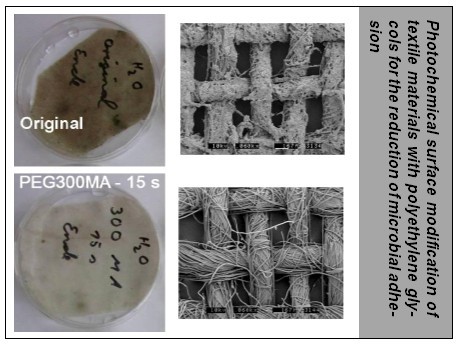

Media for liquid filtration with anti-fouling finish

Deutsches Textilforschungszentrum Nord-West e.V., Krefeld

Textiles for liquid filtration are prone to bio-fouling, especially if applied in water filtration and purification. Bio-fouling is caused by primary adsorption of proteins and microorganisms and the ensuing formation of a bio-layer on the fibers. It is understandable that bio-fouling reduces performance – necessitating frequent cleaning – and even lifetime.

The Deutsches Textilforschungs-zentrum Nord-West e.V. has developed an innovative antif- fouling finish for filters and other technical fabrics, which is based on a thin coating of polyethylene glycol (PEG). Due to this finish, the bio-fouling in aequeous environments is effectively minimized even periods of several months. In contrast, untreated fabrics show massive deposition of microorganism after only 2 weeks. PEG has thus shown to provide a cost-effective and non-toxic alternative to conventional finishes.

In addition, further experiments have shown that the already minimized bio-film is easily removed from the PEG-coated surface, e.g. by rinsing with clean water. It can be concluded that the finish not only reduces to primary adsorption, but also the adhesion of proteins and microorganisms.

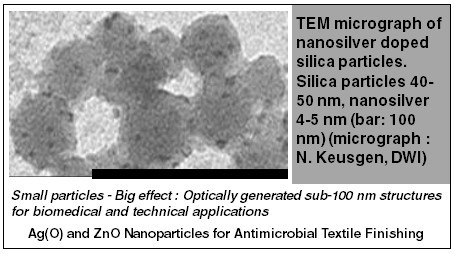

Small particles – big effects

Interactive Materials Research DWI at RWTH Aachen University and ITMC, RWTH Aachen University

Silver compounds have been used as antimicrobial agents for centuries, from the use of coins to preserve water in ancient Greece to silver containing fibers for medical or technical devices nowadays. Silver nanoparticles are already commercially used for the hygienic finishing of textiles. Zinc oxide is a material which is well-known in pharmaceutics and cosmetics due to its anti-septic, wound healing and whitening properties. Scientists of DWI at RWTH Aachen University for the first time combine silver and zinc oxide particles and thus widen the spectrum of efficacy and possible applications.

Silver compounds have been used as antimicrobial agents for centuries, from the use of coins to preserve water in ancient Greece to silver containing fibers for medical or technical devices nowadays. Silver nanoparticles are already commercially used for the hygienic finishing of textiles. Zinc oxide is a material which is well-known in pharmaceutics and cosmetics due to its anti-septic, wound healing and whitening properties. Scientists of DWI at RWTH Aachen University for the first time combine silver and zinc oxide particles and thus widen the spectrum of efficacy and possible applications.

Thereby, the size of the silver and zinc oxide particles is of outmost importance. The smaller the particles, the bigger is the relation between surface area and size and thus the efficacy. Extremely small particle sizes of silver give a large biologically active surface that leads to an enhanced antimicrobial effect. Via deposition of nanosilver particles on other nanoparticles the active surface of the nanosilver can be further enhanced.

Correspondingly, the antibacterial properties of zinc oxide increase substantially when particle sizes are reduced to nanoscopic dimensions. Similar to titanium dioxide, the effect is ascribed to photocatalytic properties. In the presence of oxygen and water, reactive oxygen species are formed on the surface of the zinc oxide nanoparticles which kill bacteria – like hydrogen peroxide being used for disinfection. At the same time, zinc shows low toxicity and also wound healing properties because of its role as a cofactor for multiple enzymes involved in wound healing processes.

Correspondingly, the antibacterial properties of zinc oxide increase substantially when particle sizes are reduced to nanoscopic dimensions. Similar to titanium dioxide, the effect is ascribed to photocatalytic properties. In the presence of oxygen and water, reactive oxygen species are formed on the surface of the zinc oxide nanoparticles which kill bacteria – like hydrogen peroxide being used for disinfection. At the same time, zinc shows low toxicity and also wound healing properties because of its role as a cofactor for multiple enzymes involved in wound healing processes.

At DWI, nanosilver and zinc oxide nanoparticles were used together for the first time. The combination of both substances leads to an increased antimicrobial effect in relation to the respective single systems. The challenge is to produce especially small particles and to jointly fix silver and zinc oxide nanoparticles onto textile fibres. Textiles finished with these nanoparticles are of special interest for biomedical applications.

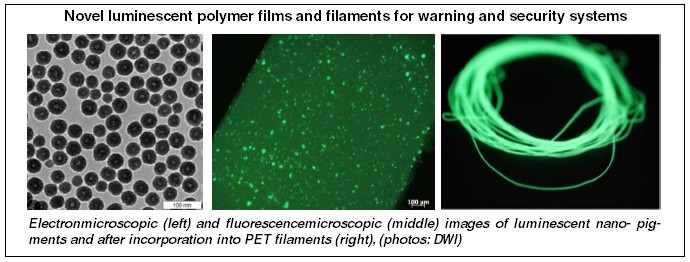

Luminescent pigments for warning and security systems

DWI at RWTH Aachen University and ITMC, RWTH Aachen University

For warning and security systems, e.g., in the textile and clothing industry or in paper industry, fibres, textiles and foils are used which gleam in the dark. For this purpose, polymer materials like filaments or films are dyed with luminescent pigments. Together with the Lehrstuhl fur Feststoff- und Grenzflachenverfahrenstechnik (LFG) of the University Erlangen-Nuremberg and the Institut fur Textiltechnik of RWTH Aachen University, scientists of DWI at RWTH Aachen University have developed novel nanopigments with excellent luminance. Already low pigment dosage is expected to result in better light, heat and wet fastness compared to conventional systems.

Different methods are being used to produce the luminescent nano-pigments. One possibility is a bottom-up approach where the pigments are formed by precipitation synthesis. Alternatively, larger particles are grinded to nanometer scale in a top-down procedure. The crucial stabilization of the grinded particles is achieved by addition of dispersing agents or stabilizers in order to avoid agglomeration.

The nanoparticles consist, e.g., of zinc sulfide, doped with copper or manganese. But also uncommon substances like strontium aluminate or yttrium oxysulfide are investigated which are doped with the so-called rare earth metals europium and dysprosium. Furthermore, organic dyestuffs and pigments are investigated, some of them after encapsulation into silica nanoparticles.

Thus, a broad spectrum of nano-particles is available which can be added to a polymer melt and extruded to films and filaments. The synthesis of the luminescent pigments is the first challenge. At this processing stage, it is important to evenly distribute the particles in a liquid formulation or a polymer master batch. Different commercially available and newly developed dispersing agents are studied for their potential to stabilize the particle dispersion in liquid formulations or the polymer melt.

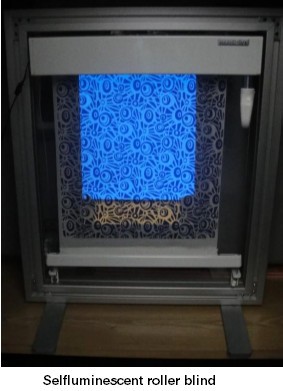

Selfluminescent textiles on the basis of renewable energy sources

Research Institute for Textile and Clothing (FTB)

The development of selfluminescent textiles has been subject of textile research for almost 10 years. Latest results by the FTB show that inherent electric conductive polymers which are the necessary basis of these luminescent systems can be applied in the form of new and aqueous dispersions via coating technology. Adhesion, cohesion as well as the luminescent effect of the newly developed multilayer coatings will be described by the help of experimental results.

The development of selfluminescent textiles has been subject of textile research for almost 10 years. Latest results by the FTB show that inherent electric conductive polymers which are the necessary basis of these luminescent systems can be applied in the form of new and aqueous dispersions via coating technology. Adhesion, cohesion as well as the luminescent effect of the newly developed multilayer coatings will be described by the help of experimental results.

This improved technology will enable the textile industry to adopt such products into their product range as they can be realized by conventional coating machines under environmentally friendly conditions now.

Furthermore the possible combination of electroluminescence with renewable energy sources will be described in order to realize light emitting textiles which are independent from any power supply system.

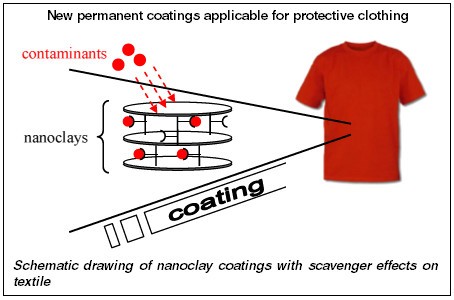

New effective coatings for protective clothing

Research Institute for Textile and Clothing (FTB), Niederrhein University of Applied Sciences and DWI at RWTH Aachen University e. V.

Layered silicates, also known as nanoclays, are inexpensive and non-toxic minerals widely used both as fillers in e.g. cosmetics, pharmaceutics or polymers, and as adsorption and decolorizing agents for industrial waste water treatment. However, there is no application for textiles using the high scavenger capacity of nanoclays for removing specific substances from the air.

Within a new research project new coating systems based on nanoclays with high scavenger effects for organic contaminants and environmental toxicants are developed. Therefore, various chemically modified nanoclays are prepared and investigated in order to obtain a high uptake of contaminants and a permanent adhesion of nanoclays to textile materials.

Thus, such coatings can be used e.g. on textiles to avoid contact of human skin with toxic and other harmful substances. The textiles coated this way have a great potential in the areas of protective clothing, personal protection, and emergency management as well as for home and construction uses (curtains, tents, etc.).

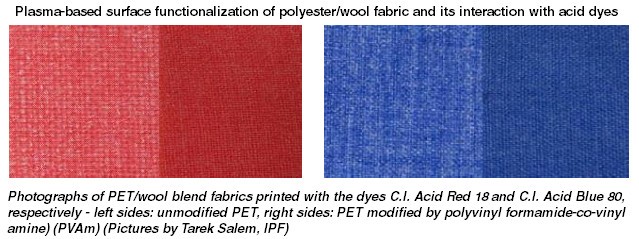

Improved receptivity for dyes and adhesion properties of PET owing to new surface modification

Results of the PhD work of Tarek Salem from the Leibniz-lnstitut fur Polymerforschung Dresden e.V. (Leibniz Institute of Polymer Research Dresden) open up new applications for poly(ethylene terephthalate) (PET or polyester), the main synthetic polymer in today’s fibre industry and the production of fabrics.

Plasma treatment and subsequent coating by polyelectrolytes allowed to functionalize the PET surface introducing amino groups that can be used for different reactions. This is of practical relevance in particular for coloration processes.

Owing to the amino groups, the PET fibres can be coloured directly by binding of the dye molecules at the fibre surface. Consequently, it becomes also possible to homogeneously dye PET/wool blends in one single coloration process.

Future applications could be ‘chameleon textiles’ that change colour in dependence on environmental stimuli (pH, temperature), indicating thus, e.g., risk potential or changes in the skin pH of injured people.

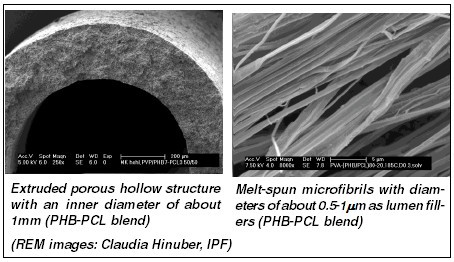

Hollow fibres and textile structures made of PHB for regenerative therapies in medicine

Scientists of the Leibniz-lnstitut fur Polymerforschung Dresden e. V. (Leibniz Institute of Polymer Research Dresden) have developed innovative textile structures for applications in regenerative therapies combining competences of the institute in the fields of biocompatible and biofunctio-nal polymer materials with-know how and equipment available for extrusion and melt spinning of polymers (single and mulitfilaments, hollow fibres, bicomponent fibres).

An embroidery technique serves to produce highly porous fabrics from a degradable material for instance poly(3-hydroxybutyrate) (PHB), which is known to be used in tissue engineering. Biochemical surface modification allows to create specific functionalities in these scaffolds: E.g., cell growth can be stimulated by ECM proteins, incorporated therapeutic agents (e.g. antibiotics) ensure a local, low-dose effect, and the colonization of the scaffold with autologous mesenchymal stem cells improves the bone ingrowth and bone formation in the scaffold after implantation into the organism.

An embroidery technique serves to produce highly porous fabrics from a degradable material for instance poly(3-hydroxybutyrate) (PHB), which is known to be used in tissue engineering. Biochemical surface modification allows to create specific functionalities in these scaffolds: E.g., cell growth can be stimulated by ECM proteins, incorporated therapeutic agents (e.g. antibiotics) ensure a local, low-dose effect, and the colonization of the scaffold with autologous mesenchymal stem cells improves the bone ingrowth and bone formation in the scaffold after implantation into the organism.

For therapy and reconstruction of large bone defects, e.g. in long or skull bones, the scaffolds have already been tested in animal experiments.

Recently, the researchers deal with the development, i. e. manufacture and biomolecular func- tionalization of mechanically stable, permeable PHB hollow fibres and structures for improved regenerative medical therapy of nerve injuries. The strategy of using a porous hollow fibre made of degradable biopolymers, aims at bridging the gap between severed nerve ends by supporting oriented neuronal regeneration processes, ensuring the nutrient transport and enabling functional recovery.

Tubular structures of varied dimensions are produced by microextrusion and melt spinning, which allows to create hierarchic structures imitating natural ones. Techniques of bio-surface engineering with appropriate ECM proteins and growth factors are applied to increase enhanced cell adhesion and to influence cell growth and cell migration.

Degradable porous structures with topographic and biomolecular key stimuli are considered to be highly promising for regeneration of large peripheral nerve defects.

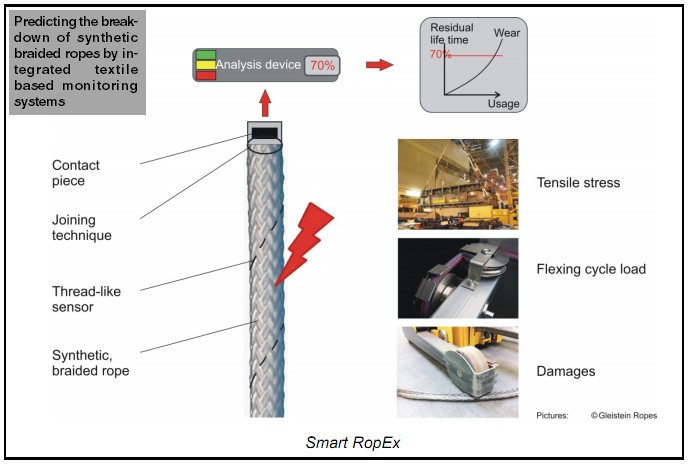

Predicting the breakdown of synthetic braided ropes

Institut fur Textiltechnik, RWTH Aachen University

Aim of this project is to develop a textile-based monitoring system that is integrated in synthetic ropes. It will predict the ropes residual life time.

This system is being developed for three new applications of synthetic fiber ropes: elevator-ropes, lifting-slings and winch-ropes.

Made of high performance fibers they offer a four to five times higher specific strength combined with an aprox. 30-35% lower weight compared to conventional wire ropes. They are able to outmatch today’s state of the art steel wire ropes.

Though they are more expensive than conventional wire rope solutions these new ropes have to keep up with ongoing product developments regarding economic aspects during their whole service life. A non-destructive monitoring, showing the residual life time, could help to utilize the full product life cycle.

Additionally the monitoring of the actual load case will lead to increased safety. Both aspects are required for a complete acceptance of synthetic ropes in the market. Within the project a prototype of the entire monitoring system for each application will be developed, showing the residual life time of the rope.

Therefore the following subgoals have been defined :

- Definition of parameters that can be used to predict the residual life time. The used parameters will be based on the change of electric resistance due to changing elongation. Additionally a statistic as well as a physical breakdownmodel of the rope is developed.

- Several thread-like sensors, measuring these parameters, are developed.

- The sensors are integrated in each application in an appropriate way to guarantee an optimal measurement of each parameter.

- A joining technique to connect the sensors to the electronics is developed, using a special contact piece between both.

- An analysis device is developed to actually examine these parameters and show the residual life time of the ropes.

The project aims are derived from achievements of the former project “Smart Rope”.

In this project monitoring systems were integrated into ropes to improve functional reliability by showing the actual load case of the ropes. But just displaying these conditions does not allow drawing conclusions concerning the residual life time. To do so, actual conditions and service life criteria have to be combined.

To identify the optimal moment to replace the ropes, reliable parameters are essential to calculate the residual life time and are therefore a necessary step towards a complete monitoring system. Hence the grade of occurred damages and the expectable service life will be displayed.

The focus of the developments lies on criteria that can be evaluated electrically. This way it will be possible to gather information about the residual life time by attaching the analysis device each and every time. Ropes could be replaced efficiently and economic just in time: Right before breakdown and not too early. This makes the whole application very efficient and economical reasonable. Cost-value-ratio is perfect for expensive applications like elevator ropes, lifting-slings and winch-ropes and safety is warranted at every point of time.

Have a good rest…!

Institut fur Textiltechnik, RWTH Aachen University

The project, AII4Rest, is focused on the development of comfort-improving rest systems, which promote deeper, more restorative sleep and prevent nocturnal awakenings. The successful solution will reduce awakenings and/or reduce time to fall to sleep again after an awakening and reduce sleep onset latency.

Millions of people suffer from sleep disorders. Medical reasons account for some cases, while lifestyle factors such as stress, eating habits, jetlag or shift work afflict others. Getting good, restorative sleep is not just a matter of hitting the pillow at night and waking up in the morning. Regulated by the body clock, nighttime rest consists of sleep cycles with specific sleep stages, all vital for health. The Improvement of these sleeping needs, cycles and stages can help people get better sleep. If people continuously do not get the amount of sleep they need, they suffer from drowsiness, lack of concentration, irritability, increased risk of falls and accidents, and lower productivity.

Sleep problems can be related to an uncomfortable mattress or sleep bedclothes resulting in suffering of short sleep cycles, low back discomfort, pain, or stiffness and shoulder pain. The rest system (formed by mattress, bedclothes, pyjama and pillow) should be as comfortable as possible to users and comfort concept depends on physical and thermal parameters.

Four different research areas will improve the quality of the rest system. The research areas and the consortium of the project are shown above.

The research area of green materials and green process technologies focuses on ecological alternative materials. Natural fibres (e.g. flax, cocos) are processed due to biological sustainability (e.g. without chemical treatment).

The research area of encapsulated systems focuses on the microencapsulation of scenting additives and phase change materials onto fibres. These phase change materials provide comfort through changing thermal conditions.

The research area of heatable textiles deals with thermal comfort improvement. The mattress is heated by electroconductive smart textiles. The electroconductive characteristics are integrated into the textile structure by inkjet printing and the use of metal fibres.

The research area of textile sensors envisages the monitoring systems to derive the sleeping quality. The sensors will be integrated into the mattress system. Two different kinds of sensors will be developed. The first sensor monitors the position as well as the movement. By electronic evaluation of the signal, the quality of sleep will be derived. The second sensor will be integrated into the protective cover. It measures the temperature between the mattress and the sleeping person. The temperature sensor will stear the heating system to control the thermoregulation.

The aim of the project is to develop overall methods for better sleeping quality by adapting to the changing human sleeping environment.

Research on “Green” Materials & Processing Technologies

Main objective of this research area is research and development of ecological and economical alternatives in fabrication processes of rest elements, which are also new technologies to improve the comfort parameters of resting systems.

Looking for this goal a study of biofibres and enzymatic and plasma technology summarizes the state-of-the-art on breakthrough technologies on textile industry (as plasma technology or enzymatic treatments) but also on emerging new materials and products that are used for manufacturing textile end-products (as biofibres or water-based nanofinishing products).

It must be to kept in mind that the end-user’s possibilities to select a product, manufactured with “green” materials & processing technologies, can be a critical topic to select one product or another.

Different materials were selected and finishing formulations and plasma treatments were identified and carried out. This approach (and pretests done) is needed in order to establish scientific/technical guidelines for further formulations and treatments of several materials.

A compilation of several suppliers of mattresses and bedclothes producers shows that common textile materials used in these end-products destined to rest are usually a mixture of natural and synthetic fibres. For mattresses, some mixtures and textile materials are used (combinations -varying compositions- of Viscose/PES, PES/Acrylic/PA, PES/Viscose/PA, PES/PP, PES/CO (FR), CO/PES, PVC-coated/PES… or full textile materials as PES 100%) and for bedclothes CO 100%, PES 100% and their mixtures.

Research on new textile materials to develop new fabrics for mattress ticking and bedclothes gave a selection of new materials: Bamboo (is being used for mattresses but not for pyjamas), Soya, polylactic acid (PLA) and chitosan (for mattress ticking, bedclothes and pyjamas).

To complete this selection, a study of enzymes was done to develop further formulations (in order to improve soft handle and physical comfort): Amylase/pectinase (desizing), Catalase (bleaching), Peroxidase (dyeing), Cellulase (biostoning). Enzymes and nanofinishings are destined to improve handle and functional properties on fabrics. Main requirements detected and interesting functionalities for the (nano)finishing application on fabrics destined to mattress ticking and bedclothes :

- Abrasion resistance.

- Pilling.

- Moisture management.

- Flame retardancy.

- Health properties (antibacterial, antiodour, vitamin delivery, skin care.).

- Durability and washing fastness of these properties.

Use of nanofinishings can improve the performance of the fabrics due to the increased penetration rate of product into the fibres (due to the nanostructured dispersion of the finishing product).

One of the developed formulations to obtain soft handle on cellulosic-based fabrics is shown here :

- 15 g/l : Nanosilicon

- 0.5 ml/l : Acetic acid (80%)

- Padding application. Pick-up: 60%

- Drying 100-120°C, polymerisation: 160-170°C (1 min)

Plasma treatment was studied in order to improve wettability and bonding forces between adhesives/finishings and fabrics. Low pressure plasma and corona plasma were applied.

Plasma treatments on polypropylene (PP) substrates showed that the low surface energy of this kind of material can be increased, but also on polyester (PES) fabrics. Wettability of these textile materials is improved, but we need a further characterization of delamination forces (when a gluing process between foam and a fabric will be applied), in order to ensure the enhancement of the adhesion or a reduction of the adhesive required for laminating.

Research and Development of Microencapsulation Systems for Comfort Improvement

This work in this research area is dedicated to microencapsulation. These microcapsules, either loaded with phase change materials (PCMs) or scenting additives, are incorporated into the mattress system to improve thermal comfort and enhance the sleep quality.

PCMs are materials that can absorb a lot of thermal energy by exploiting melting heat. They act as a thermal buffer in warm and cold conditions. The aim in All4Rest is to determine the right quantity of PCMs in a mattress system, as they should not be used in excessive quantities. First of all they may interfere with the handle of the fabric or with its mechanical properties (e.g. strength). Secondly conditions may change and when the buffer capacity is too big, the reaction of the system becomes too slow causing overregulation.

Hence, we coated different mattress ticking fabrics with various concentrations of microcapsules loaded with PCMs.

So far, we observed that the loaded of the microcapsules depends on the fabric type as well as on the chemical formulation of the treatment solution.

Research and development of heatable textiles for thermal comfort improvement

The work in this research area is concentrated on the development of textile resistive heating systems. Although resistive heating is one of the few technologies in the field of smart textiles that is applied in industry, little information is reported on its theoretical background: What is the relation between the initial electrical resistance and the achieved temperature increase? Which are possible set-ups of the heating circuit, e.g. series and parallel connections? These are questions that need to be answered within All4Rest.

Development of Sensors into textiles

The aim of this research area is the development of sensors which are integrated in the mattress system. Two different kinds of sensors will be developed : an activity sensor which monitors the position of a sleeping person and its movement during the periode and a temperature sensor which reacts toward the heatable system. The development of an electronic and software evaluation system is part of the workpacket as well.

Different conductive fibre materials were tested to determine which material can be integrated into the textiles and withstand the repeated load cycles imposed on it without breaking the electrically conductive filaments, which would render the sensor useless. The material which will be used for the sensors depends on the sensor principle which, in turn, depends on the mattress system. The yarn which will be used as conductive paths needs to have a low electrical resistance for low electrical losses. The conductive yarns will be responsible for the transmission of the electrical signals between the sensors and the measurement unit.

Possible sensor systems for the activity sensors are:

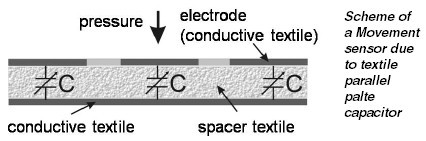

Capacitive Sensor Systems

A capacitor is an electric component consisting of two opposing electrodes that are divided by an insulating material. When a voltage is applied to the circuit, the electrodes are charged positively and negatively. There is no electric current in the system, since the insulator prevents the flow of electrons. Between the charged electrodes an electric field is built up. Basically a capacitor is an energy storage element, often used in electric circuits to buffer fluctuations in the power supply. As the capacity is dependent on the distance between the electrodes, capacitors can be used as pressure or deformation sensors. Multiple electrodes are arranged on a textile surface, opposed to a base electrode on the other side of the structure. The electrodes are separated by a flexible material. As the textile is exposed to mechanical pressure (resulting in deformation), the distance between the electrodes varies, resulting in a change of the electrical capacity. By using several electrodes (capacitors), the distribution of pressure can be measured. This principle can also be applied in the project All4Rest.

Resistive Sensor Systems

The electric resistance of a material is determined by the material itself, and the geometric shape of the conductor. In general, Ohm’s law is applied to calculate the electric resistance. In the All4Rest project, this principle could be applied to measure the pressure by applying conductive fibres in the textiles that are bent and deformed when a mechanical load is applied to them. Measuring elongation using the electrical resistance is a well-known concept in Smart Textiles technology.

Capacitive Proximity Sensor Systems

Capacitive proximity switches sense distance to objects by detecting changes in capacitance around it. A radio-frequency oscillator is connected to a metal plate or in our case a conductive coated textile. When the textile nears an object, the radio frequency changes, and the frequency detector sends a signal telling the switch to open or close.

These proximity switches have the disadvantage of being more sensitive to objects that conduct electricity than to objects that do not. The human body is a good conductor of electricity. There are several charged ions all over the body, and when an electric field is applied, they align in the direction of the field.

For the use in a mattress it appeared that the best option for a pressure sensor is the capacitive sensor system. Spacer fabrics are already in use in mattress systems and therefore the production of the mattress has not to change a lot. The spacer fabric which is already used into the mattress for thermal comfort will be coated with a CNTs layer.

The coating will be placed in some strips on the deck areas of the spacer fabric. When the distance between the two Carbon Nanotubes (CNT) coated deck areas changes, as a result of a person who is changing position while sleeping, the conductivity changes and the signal will be transmitted to the measurement unit.

Temperature sensor

The temperature sensor will be placed on the surface of the mattress. It will be integrated in a protecting layer under the bed sheet. Two different kinds of possible temperature sensors are known in the literature :

Thermistor

The word thermistor is a portmanteau of thermal and resistor. Therefore a thermistor is a type of resistor whose resistance varies significantly with temperature. Thermistors are used as temperature sensors. Thermistors differ from resistance temperature detectors (RTD) in that the material used in a thermistor is generally a ceramic or polymer, while RTDs use pure metals. The temperature response is also different; RTDs are useful over larger temperature ranges, while thermistors typically achieve a higher precision within a limited temperature range [usually -90°C to 130°C].

Thermocouples

A thermocouple is a device consisting of two different conductors (metal alloys) that produce a voltage proportional to a temperature difference between either ends of conductor pair. They are based on the Seebeck Effect or Thermoelectric Effect that occurs in electrical conductors that experience a temperature gradient along their length. The thermoelectric effect is the direct conversion of temperature differences to electric voltage and vice-versa. A thermoelectric device creates a voltage when there is a different temperature on each side. Conversely, when a voltage is applied to it, it creates a temperature difference. This effect can be used to generate electricity, measure temperature or change the temperature of objects. Because the direction of heating and cooling is determined by the polarity of the applied voltage, thermoelectric devices are efficient temperature controllers.

Therfore thermocouples are a widely used type of temperature sensor for measurement and control and can also be used to convert a heat gradient into electricity. In contrast to most other methods of temperature measurement, thermocouples are self powered and require no external form of excitation. In the case of textile temperature sensors, two diffrent coated yarns will be used as conductors. The coating depends on the difference of thermoelectric voltage, shown in the table below.

Table : Thermoelectric Voltage

Material Thermoelectric Voltage [k / (mV/100K)]

Constantan 3.2

Nickel 1.9

Platinum 0.0 per definition Wolfram 0.7 Copper 0.7 Iron 1.9 Nichrome 2.2

Two different metal coatings, which have a large range different in the thermoelectrical voltage, will be used as temperature sensors. First trials showed that the Bekaert-Bekinox yarns, which are made of stainless steel, have a similar temperature curve as the reference thermocouple wires.

In further tests the Bekaert-Bekinox yarn will be paired with nickel coated yarn. The electrothemical difference between iron and nickel is 3.8 k/(mV/100K). As stainless steel is similar to iron, this couple seems to be a good combination. The results will be measured in voltage.

The overall aim is to result in an intelligent mattress system that integrates all described components in one system.

However, for the time being, the different research approaches will separately continue until their technological maturity level allows their integration in one complex mattress design.

Another possibility is that the system will work as an add-on system as the functionality of the whole system is independent of the integration of all systems. Hence, it is possible to use the movement sensor, for instance, to quantify the quality of the sleep together with each single improvement component.

Fibers for medical application – Chitosan into shape

Institute of Textile Machinery and High Performance Material Technology Heppe Medical Chitosan GmbH (HMC+)

Due to its adsorbing, haemostatic, antimicrobial and curative effect, the polyaminosaccharid chitosan is a material which is suitable for medical use and, therefore, for the production of medical products. Thus, chitosan is applied in the treatment of wounds, in the specific active substance release (drug delivery), as an active substance transport system, in food supplements and in cosmetics. Chitosan could also be used for the presentation of biological fabric constructions (Tissue Engineering), in regenerative medicine and as a substance for the necessary structural scaffolding, which is biodegradable after the successful cell settlement. Some textile products with shares of the biopolymer chitosan are already commercially available; however, no material based on pure material can be found, so that in the Institute of Textile Machinery and High Performance Material Technology (ITM) at Technische Universitat Dresden, it was found necessary to process filament yarns without admixtures.

Since the ITM has a modern wet spinning system and has been able to work together with the Heppe Medical Chitosan GmbH (HMC+) as a highly competent partner in the presentation of various chitosan characteristics in medical quality, first substantial results could be achieved in the first treatment period of a publicly promoted project. Thus, it has been possible to produce different threads according to the solvent wet spinning procedure in a kg scale.

All generated products can be distinguished by their stability and high purity standards as it could be shown by means of textile-physical and chemical analysis technology. So, textile filament yarns, which hold absolute biocompatibility and can easily be further processed in textile-technical processes, are obtained. Fabrics could be manufactured after knitting and weaving processes from the yarns produced at the ITM, which can now be applied in medicine. These new, innovative developments reveal possibilities such as the realisation of completely new scaffolds, which could have only been imagined so far.

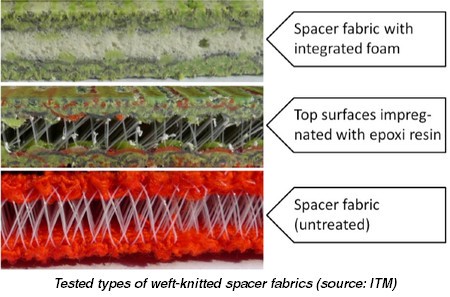

Improvement of compressive strength of weft-knitted spacer fabrics

Institute of Textile Machinery & High Performance Material Technology

Pedestrian protection gets more and more importance with the development of modern passenger cars. For this reason, weft-knitted based textile spacer fabrics are being tested due to their improved abilities for mechanical, thermal and acoustic properties. Due to the high amount of dynamic load during a passenger accident, the compressive strength has to be increased to a great extent which cannot be realized by the modification of material and manufacturing-methods of the textile structure. To use the little available deformation space, the load has to be distributed on a larger area. Sandwich structures with full or local consolidation of one or both of the top surfaces of the spacer fabric and additional materials which is brought between the top surfaces can provide these properties. It is a starting point for new applications of textile spacer fabrics.

Pedestrian protection gets more and more importance with the development of modern passenger cars. For this reason, weft-knitted based textile spacer fabrics are being tested due to their improved abilities for mechanical, thermal and acoustic properties. Due to the high amount of dynamic load during a passenger accident, the compressive strength has to be increased to a great extent which cannot be realized by the modification of material and manufacturing-methods of the textile structure. To use the little available deformation space, the load has to be distributed on a larger area. Sandwich structures with full or local consolidation of one or both of the top surfaces of the spacer fabric and additional materials which is brought between the top surfaces can provide these properties. It is a starting point for new applications of textile spacer fabrics.

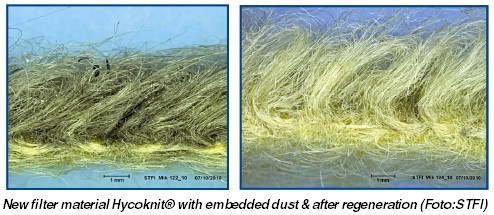

Filter media of high-tech fibres for cleaning of exhaust gas

Sachsisches Textilforschungs-institut e. V., Chemnitz

Replacing fossil fuels for heat and power generation by biomass combustion processes is a main topic and challenge during the coming years. By increasing the number of biomass heating systems without additional gas cleaning high dust load of the ambient air will be created. In case of this a new law for emissions (1. BlmSchV) has been given by German government. Stage 2 of this policy is valid until 2015 and restricts the emission value for dust down to 20 mg/m3.

Therefore a downstream filtration for biomass flue gas will be required in the end of 2014. It is needed for all biomass boilers with a heat generation capacity more than 4 kW. To get a new solution for this problem a new filter material is developed.

Important for the function of furnace is a low resistance of filtration system. Second topic is a high resistance of filter media against the chemical aggressive flue gas. In a current research project the complex achievement of requirements new filter media with thermal and chemical stability while exposed to flue gas, high air permeability, excellent dust storage capacity, regener- ability and good fine dust separation efficiency are considered.

Contents of presentation will be results of fiber resistance tests, filter media manufacturing and characteristic properties of new filter media for exhaust gas cleaning.

Embroidery technology and machines for technical applications

Sachsisches Textilforschungs-institut e.V., Chemnitz

HighSTICK® is an innovative regional growth core funded by the German Federal Ministry of Education and Research. It was founded in 2007 to initiate a diversification process by using already available technology and to open up new market fields for small companies which are almost established in embroidery to find new applications in technical products. Twenty-eight partners from embroidery industry, textile finishing, electronic industry and mechanical engineering as well as R&D institutions are involved in the projects. Nine different projects in building textiles, mobile textiles and medical textiles were carried out. STFI is involved in three different research projects.

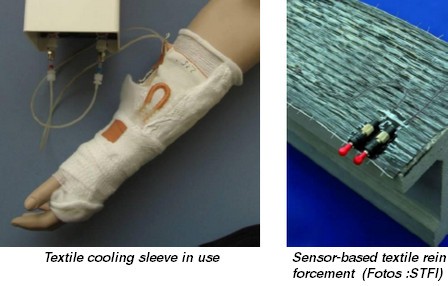

Textile cooling sleeve for applications under cast

Controlled cooling of bone fractures under cast to speed up the swelling decrease, especially for fractures of forearm and ankles

Sensor-based textile reinforcement

Continuous and/or periodical recording of changes caused by damages or stress at bearing structures and buildings having a high damage potential in case of failure

Embroidered textile panel heat systems

Development of innovative embroidered panel heat systems for reconstruction of old buildings and construction of new buildings

In the scope of the projects new products for technical applications on the basis of the embroidering technology were developed. Prerequisite for these was the development of new assemblies and machinery. At present the new products are introduced into the market.

(Courtesy : “Aachen-Dresden” DWI at RWTH Aachen University, Institute of Textile Machinery and High Performance Material Technology)