The market for recycled textiles is growing rapidly – because fashion is faster than ever, environmental regulations are stricter than ever, and the consumer focus on sustainability is sharper than ever. That’s why companies around the globe are seeking solutions to the key challenges involved in turning textile waste into high-quality yarn. Truetzschler is now launching an intelligent card that is specifically designed for this application. It’s called the TC 19i for Recycling.

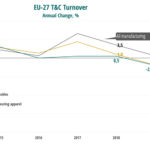

Sustainability is transforming every aspect of the way people live and work, from renewable energy or electric vehicles through to packaging-free supermarkets. In the textile industry, the market for recycled fibers is growing at high speed because it taps into two contradictory trends: First, consumers buy more clothes but throw the clothes away much sooner; this is known as “fast fashion”. And second, consumers are increasingly eco-conscious and want more sustainable textile products.

Due to this high demand, as well as lower raw material costs and potentially higher profit margins, many companies are now exploring ways of producing high-quality yarns from recycled fibers – but it’s a difficult task. Waste from yarn or garment production, as well as used textiles or garments, present a wide range of challenges in spinning preparation, where the later quality of the yarn is being determined. Known as “hard waste”, secondary fibers from torn waste contain unwanted yarn or fabric particles that reduce the quality of the final output and can impair the carding performance. They also contain a high amount of short fibers, which can have a negative impact on yarn strength.

Here’s how the TC 19i is able to achieve these results:

- Gentle but effective tuft opening: Our new WEBFEED has components such as the wired licker-in with stationary carding segments and improved profile geometries that are specifically designed for recycling applications. The recycling knife ensures the removal of disruptive particles and minimizes the loss of good fibers.

- Robustness and reliability: Secondary fibers from torn waste may adhere to the surfaces of material carrying parts and lead to fiber blockages. With TC 19i for Recycling, this cannot happen because all material carrying parts consist of stainless steel. Moreover, the robust design and innovative coatings of key parts guarantee reliable performance in almost any application.

- More value from waste: Our gap optimizer T-GO for Recycling uses sensors and algorithms to monitor and automatically adjust the ideal carding gap for the material involved, even under changing production conditions. In this way, it maximizes quality and productivity during recycling.

- Flexibility: Our MULTI WEBCLEAN system enables fast, flexible and customized adjustments to recycling applications. Eight elements in the pre- and post-carding zone can be configurated either as carding or cleaning element or cover profile. This flexibility empowers customers to achieve the best possible configuration for their specific process.

- Good advice and hands-on service: The TC 19i for Recycling, as well as Truetzschler installations for recycling as a whole, stand out due to their high number of possible configurations. Truetzschler supports each customer with recommendations for ideal settings and makes sure that customers’ production goals are actually realized.

Staying ahead of consumer demand and regulations

“By producing high-quality sliver from recycled fibers for new yarn, our customers are able to make progress toward their targets for sustainability, while also staying ahead of rising regulatory pressure and increasing consumer demand for eco-friendly products”, says Markus Wurster, Head of Global Sales. The TC 19i for Recycling is an intelligent card that helps companies in the textile industry to embrace sustainability and turn this megatrend into a mega opportunity.

40% reduction in yarn faults and 40% increase in production

With the TC 19i card, textile manufacturers achieve a 40% reduction in yarn faults and a 40% increase in production. Designed especially for recycling applications, the new WEBFEED has components such as a cable licker-in with fixed carding segments and improved profile geometries. The recycling blade minimizes good fiber loss while at the same time ensuring the removal of disruptive particles.

Secondary fibers from torn waste can adhere to the surfaces of material-carrying parts, causing the fibers to clog. This is not a problem, as all material-bearing parts of the TC 19i are made of stainless steel. What’s more, the robust design and innovative coatings of key parts guarantee reliable performance in virtually any application.

The range optimizer T-GO uses various sensors and algorithms to monitor and automatically adjust the ideal carding gap for the relevant material, even under changing production conditions. In this way, quality and efficiency reach the highest level during recycling.

My Shop – Truetzschler service never sleeps

In 2019, Truetzschler expanded its service range with its own online shop. Thanks to the “My Shop” online platform, customers can now order spare parts for spinning preparation systems as well as card clothings for their machines – around the clock and 365 days a year.

“My Shop”, along with “My Mill”, “My Production” and “My Wires”, is one of the digital solutions that are brought together under the “My Trützschler” umbrella platform. The global identity service “My Identity” provides the key to the entire digital Truetzschler world: Once you have registered, you can access all available Truetzschler online applications simply.

The “My Shop” application promises customers of Truetzschler Spinning and Truetzschler Card Clothing a varied product range and a straightforward, practical process: When accessing the online shop, the customer – or customer representative – is directed to the relevant page of the Spinning or Card Clothing shop because the system automatically assesses requirements based on the user’s identity. If the user is matched to both areas, they can simply select between “My Shop Spinning” and “My Shop Card Clothing”.

“My Shop” for Card Clothing customers:

Card Clothing assessable 24/7: The newly implemented TCC online shop allows customers to make clothing orders at any time and from any location. Various search and filter functions are available to help select the right articles. In this way, individual product areas can be selected, for example. In turn, this allows a selection based on further attributes like sales units, working width etc. By narrowing down the product range, this filter makes selection much easier because only articles that are relevant to the customer are shown.

About Truetzschler recycling solutions

Truetzschler offers complete solutions for the recycling of cotton waste from spinning preparation, as well as the recycling of secondary fibers from torn textile waste: From blowroom technology for ideal opening, cleaning and blending to advanced carding and draw frame solutions. The TC 19i for Recycling and the integrated draw frame IDF 2 are benchmark in the direct spinning of rotor yarns from recycled materials. Truetzschler also provides a wide portfolio of card clothings specifically developed for recycling applications. Digital solutions and fast, reliable service complete our offer and help customers to turn waste into sustainable quality yarns.