Enzymes are proteins with highly specialized catalytic functions, produced by all living organisms. Enzymes are responsible for many essential biochemical reactions in microorganisms, plants, animals, and human beings. Enzymes are essential for all metabolic processes.

Enzymes are proteins with highly specialized catalytic functions, produced by all living organisms. Enzymes are responsible for many essential biochemical reactions in microorganisms, plants, animals, and human beings. Enzymes are essential for all metabolic processes.

Although like all other proteins, enzymes are composed of amino acids, they differ in function in that they have the unique ability to facilitate biochemical reactions without undergoing change themselves. This catalytic capability is what makes enzymes unique.

Enzymes are natural protein molecules that act as highly efficient catalysts in biochemical reactions, that is, they help a chemical reaction take place quickly and efficiently. Enzymes not only work efficiently and rapidly, they are also biodegradable. Enzymes are highly efficient in increasing the reaction rate of biochemical processes that otherwise proceed very slowly, or in some cases, not at all.

What Types Of Enzymes Are There?

Enzymes are categorized according to the compounds they act upon.

Some of the most common include; proteases which break down proteins, cellulases which break down cellulose, lipases which split fats (lipids) into glycerol and fatty acids, and amylases which break down starch into simple sugars.

Industrial Enzymes And The Environment

Enzymes can often replace chemicals or processes that present safety or environmental issues. For example, enzymes can:

- Replace acids in the starch processing industry and alkalis or oxidizing

- agents in fabric desizing;

- Reduce the use of sulfide in tanneries;

- Replace pumice stones for “stonewashing” jeans;

- Allow for more complete digestion of animal feed leading to

- less animal waste; and

- Remove stains from fabrics. Clothes can be washed at lower

- temperatures, thus saving energy. Enzymes can be used instead of

- chlorine bleach for removing stains on cloth. The use of enzymes also

- allows the level of surfactants to be reduced and permits the cleaning

- of clothes in the absence of phosphates.

Enzymes also contribute to safer working conditions through elimination of chemical treatments during production processes. For example, in starch, paper and textile processing, less hazardous chemicals are required when enzymes are used.

As our understanding of the function of enzymes has grown, our ability to selectively apply these natural substances to productive uses has continued to grow.

Industrial Applications – Textiles

Textiles Processing

Textile processing has benefited greatly on both environmental and product quality aspects through the use of enzymes. Prior to weaving of yarn into fabric, the warp yarns are coated with a sizing agent to lubricate and protect the yarn from abrasion during weaving. Historically, the main sizing agent used for cotton fabrics has been starch because of its excellent film forming capacity, availability, and relatively low cost. Before the fabric can be dyed, the applied sizing agent and the natural non-cellulosic materials present in the cotton must be removed. Before the discovery of amylase enzymes, the only alternative to remove the starch-based sizing was extended treatment with caustic soda at high temperature. The chemical treatment was not totally effective in removing the starch (which leads to imperfections in dyeing) and also results in a degradation of the cotton fiber resulting in destruction of the natural, soft feel, or hand, of the cotton.

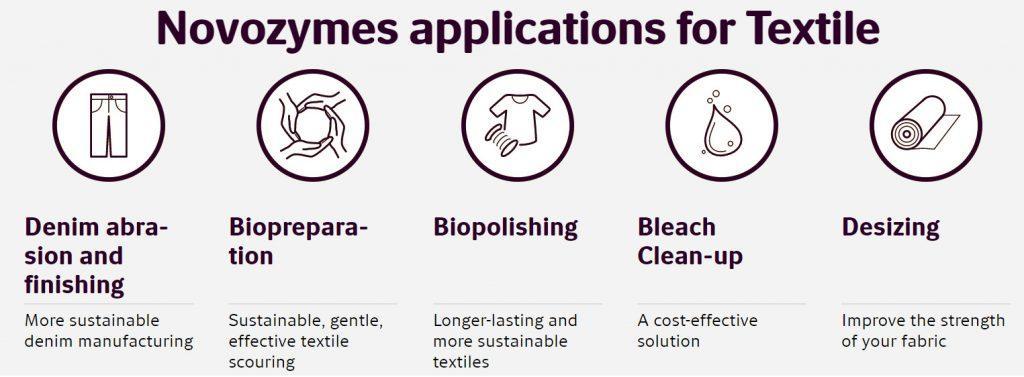

Efficient, safer, more environmentally-friendly textile processing. New opportunities are opening up in sustainable textile manufacturing. Enzymes let textile mills and laundries save energy, time and money. Consumers and brands get the high-quality, sustainable fabrics that are swiftly rising in popularity.

Efficient, safer, more environmentally-friendly textile processing. New opportunities are opening up in sustainable textile manufacturing. Enzymes let textile mills and laundries save energy, time and money. Consumers and brands get the high-quality, sustainable fabrics that are swiftly rising in popularity. (Courtesy: Novozymes)

Efficient, safer, more environmentally-friendly textile processing. New opportunities are opening up in sustainable textile manufacturing. Enzymes let textile mills and laundries save energy, time and money. Consumers and brands get the high-quality, sustainable fabrics that are swiftly rising in popularity. (Courtesy: Novozymes)

Novozymes applications for Textile processing Denim abrasion and finishing Biopreparation Biopolishing Bleach clean-up Desizing

The use of amylases to remove starch-based sizing agents has decreased the use of harsh chemicals in the textile industry, resulting in a lower discharge of waste chemicals to the environment, improved the safety of working conditions for textile workers and has raised the quality of the fabric. New enzymatic processes are being developed (cellulase, hemicellulase, pectinase and lipase), which offer the potential to totally replace the use of other chemicals in textile preparation processes.

Environmental Benefits: Lower discharge of chemicals and wastewater and decreased handling of hazardous chemicals for textile workers.

Consumer Benefits: Improved fabric quality.

Stonewashed Jeans Without Stones

Traditionally, to get the look and feel of stonewashed jeans, pumice stones were used. However, thanks to the introduction of cellulase enzymes, the jeans industry can reduce and even eliminate the use of stones. Of course, a big driver for the jeans industry is fashion. Enzymes give the manufacturer a newer, easier set of tools to create new looks.

Enzyme Preparation Made of Amylase, Cellulase, Buffers and Additives (Courtesy: Textilchemie Dr. Petry GmbH, Germany)

Enzyme Preparation Made of Amylase, Cellulase, Buffers and Additives (Courtesy: Textilchemie Dr. Petry GmbH, Germany)

Although many consumers do not want their jeans to look or feel new, they usually do not want them to look worn-out or torn. The pumice stones used to “stonewash” the denim clothes can also over abrade or damage the garment.

By using enzymes, the manufacturer can give consumers the look they want, without damaging the garment.

Environmental Benefits: Less mining, reduced waste, less energy, less clogging of municipal pipes with stones and stone dust, fewer worn out machines and pipes attributed to stones and stone dust.

Consumer Benefits: More fashion choices, longer garment life/wear due to lower damage of original fabric.

Yarn Treatment

In the preparation of cotton yarn for dyeing and garment manufacture, hydrogen peroxide is used to bleach the yarn. Normally, either a reducing agent is used to neutralize the hydrogen peroxide or water is used to rinse out the hydrogen peroxide bleach since it must be removed for proper dyeing. An enzyme, catalase, can be used to breakdown the hydrogen peroxide to water and oxygen. With the use of catalase, the reducing agent can be eliminated or the amount of rinse water can be dramatically reduced, resulting in less polluted wastewater or lower water consumption.

The benefits have been documented in a Life Cycle Analysis. Again, enzymes can help us develop sustainable processes by lowering the environmental impact we humans impose.

Environmental Benefits: Reduced chemical load, reduced water consumption, lower energy consumption.

The Enzyme Technical Association (ETA) is a trade association that represents a majority of the manufacturers and marketers of enzyme products in North, Central, and South America (“Americas”). The ETA has been in existence since 1970 and maintains an active role in the development of governmental regulations, policies and industry guidance that affect enzyme manufacturers, distributors, and customers.

(Source: Enzyme Technical Association, Washington)