Interview with Mr Anjani Prasad, Managing Director, Archroma India

Anjani Prasad is Managing Director and Head of Brand Performance Textiles Specialties for Archroma India. He is a seasoned textile expert with experience gained over 30 years working in the textile industry with companies such as Century Mills and BTRA. In 1991, he joined Clariant India as a technical executive and developed his expertise through positions including Product Manager and Head of Country for the Textile, Leather, Emulsion and Paper Division, overseeing 400 employees. In 2010, he relocated to Singapore with Asia-Pacific wide responsibilities including marketing and sustainability support to retailers and customers. After Archroma came to life from Clariant’s textile, paper and emulsion businesses in 2013, Mr Prasad was appointed as Global Head of New Business Development for the textile chemicals business, and in 2015 he returned to India as Head of Sales for the Indian market.

Mr Prasad has a B.Sc (Tech) and M.Sc (Tech) in Textile Chemistry from the Institute of Chemical Technology in Mumbai, and is a Chartered Colorist. He serves as a Director at the Indian Technical Textile Association, a Board member at Dyestuffs Manufacturers Association of India and of the Indian Specialty Chemical Manufacturers’ Association. He is a member of the Editorial Board of Colourage, the magazine for textile and garment processing and the Journal of the Textile Association.

On Company’s Products

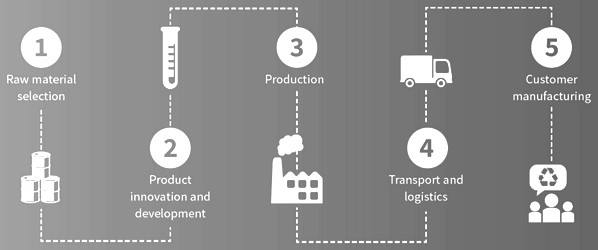

Archroma is a global, diversified provider of dyes and specialty chemicals serving the branded and performance textiles, from fiber to finish. We play a key role throughout the entire textile supply chain, with special chemicals for pretreatment, dyeing, printing and finishing of textiles. Archroma’s solution systems aim to enhance the properties of apparel and other textiles in applications as diverse as high fashion, home textiles and special technical textiles.

On the Indian textile market, global trends and the emerging challenges

Our purpose at Archroma is to help make the industry more sustainable, and we do that by continuously challenging the status quo on how colors and effects are developed and how they are applied in the textile manufacturing process. Therefore, whilst clearly the new environmental regulations in India are challenging for the industry on the short term, we also believe that there is no other way, moving forward. That is why we introduced a whole new way to look at colors and performance for textiles, with an approach based on systems. We work with our customers looking at the whole production process, and including their needs, challenges and market goals, which allows us to come up with holistic, optimized and competitive solutions. And so far the response from the Indian textile manufacturers and brand is very positive

The textile industry is going through major changes, mainly driven by the growing public concerns about how products are made and what impact they have on the environment or our health. Responsible chemical leaders such as Archroma have been developing technologies for increased safety and sustainability for many years, and we are therefore very excited to see such change happening in the textile industry. That is where Archroma comes to help textile manufacturers with our innovations and solution systems designed to optimize productivity and/or increase the value of the textile products to help our customers to differentiate on their markets.

We select our innovations and solution systems for their compliance with what we call The Archroma Way: Safe, efficient and enhanced. We help make products that are safe to use and wear, for our customer and the consumer. We help make textiles and clothing in a more efficient way, aiming to optimize productivity and the resource usage, in order to reduce the total production cost. And we help make textiles that are enhanced through functions and aesthetics to help make the final product more desirable for brands and the consumer.

————————————————————————————————————————-

Archroma’s approach to sustainability

Sustainability at Archroma essentially means being a responsible stakeholder within the value chains in which we operate. Consumers aspire to goods that bring them function, beauty … and meaning – goods that are made in a more sustainable and responsible way. Archroma makes a positive contribution to this aspiration across all its core areas. All core business units are creating powerful new processes.

Our purpose is to create chemical technologies that minimize environmental impact at all stages in a product’s life cycle, from extraction to disposal.

In order to do this, our strategy consists of pursuing 4 objectives:

————————————————————————————————————————-

Archroma’s Global Presence

Archroma is already a global player. We have presence and experts in 35 countries, and we operate with 3000 employees and 25 plants worldwide. This footprint is what makes us a reliable partner for the major global brands and textile manufacturers who need world-class and consistent quality and service levels.

On India and China

Archroma has presence in China and India. We see some shifts here and there, but we don’t build our strategy on the short term. Archroma is committed to help make our industry sustainable, ecologically but also economically, and that means supporting out customers and helping them, in both countries, to develop and solidify both domestic and export market outlets and positions. Each market comes with its own strengths and challenges, and our job is to help our customers in both countries to weather the challenges and make the most of their opportunities.

On awareness about global standards/certifications

The awareness about global standards and certifications is quite high for export. For the domestic market, however, as local brands do not require such standards and certifications, the awareness remain relatively low. In addition, there are many certifying agencies operating in India, and the textile industry would probably benefit from some consolidation here

On “Organic” products

Organic products when it comes to fibers are probably the only way to go. We need to ensure that we don’t destroy our soils and fresh water resources when we grow cotton, for instance. When it comes to dyes and effects, the problem is slightly different. Whereas natural dyes may appear at first as the best option, they actually come with problems as well, both in terms of sustainability and performance. That we why Archroma is developing solutions that combine the best of both worlds, like for instance with our EarthColors® dyes. Earthcolors® are a very exciting range. The dyes are produced in our plant of Castellbisbal near Barcelona, Spain. They are synthesized from non-edible agricultural or herbal industries waste, such as leaves or nutshells. The raw materials are sourced as close as possible from the production plant. We have currently seven dyes in the range, covering a palette of natural shades for cellulosic based fibers such as cotton, viscose, linen, bamboo, kapok, etc.

On sustainability programs

Many brands are currently developing and implementing programs to ensure more sustainable and safer sourcing and manufacturing, and we see more and more textile manufacturers doing the same. Brands like Patagonia or G-Star have adopted very early some of Archroma’s most iconic innovations, such as our Advanced Denim technology based on sulfur dyes used to color denim, our EarthColors range mentioned earlier, or our aniline-free* synthetic pre-reduced Denisol® Pure Indigo solution.

The industry as a whole has advanced very far already and our objective is clearly to help push the sustainability agenda even further. We recently joined the ZDHC Foundation as a contributor to help drive industry-wide change in responsible chemical management. Archroma is supporting the ZDHC Manufacturing Restricted Substance List (ZDHC MRSL) and the related “pyramid” conformity system designed to eliminate duplicative approaches. Such initiatives, associated with our commitment to develop innovations and systems aimed to help textile manufacturers with optimized productivity and/or value creation in their markets, will help make the textile industry more sustainable, and ensure that we protect our planet for the generations to come. Because it’s our nature.

On organised vs. decentralized textile sector

Textile manufacturers and mills will need to consider coming to proper size or scale of production, and evolve towards further consolidation, if we wish to stay competitive as an industry, both on domestic and global markets, going forward.

On the future of textile industry

The textile industry in India needs to implement best-in-class water management. The willingness is there and many textile manufacturers are looking to cluster the water effluent treatment is in order to also work on scale of operation and cost

On Archroma’s Plans

India is a very important market for Archroma and we see much potential for growth in terms of technology, expertise, innovation and creativity. We have one office and one plant in Roha, and we operate with more than 160 employees here in India. We are in the process to acquire an optical brightener business for paper and detergents from BASF, which will include a second plant in Ankleshwar. With that and for the time being, our presence and footprint in India will be in line with our current market position and plans.

On Archroma’s Mantra for success

There is no secret, other than developing a solid understanding of the needs of market, aligning fast enough, and continuously reviewing and finding solutions to help internal and external partners.