https://www.facebook.com/Circleeconomy/videos/502377030653287/

12 March 2020

Fibersort, making closed loop textiles a reality

Today, the Fibersort consortium presents the market-ready Fibersort machine to the industry: a cutting edge automated sorting technology that revolutionises textile to textile recycling of post-consumer textiles.

Fibersort: The technology to close the loop on textiles is here- it’s time for action!

The Fibersort technology can now sort around 900 kg of textiles per hour, enabling textile-to-textile recycling. Join the collectors, sorters, recyclers, brands, and other stakeholders that made this possible in this webinar and learn more about how you can contribute to closing the textiles loop.

Fibersort Interreg NWE project

“We started the Fibersort after a visit to India back in 2006-2008, where I witnessed firsthand the incredible amounts of textiles in landfill, as well as the working

conditions, mainly child labour, involved in dealing with our (European) waste. After this encounter I decided we needed to change the way we handle our discarded

textiles and started looking for a technical innovation that could provide us a more ethical and sustainable alternative.After working together with a Dutch textile recycling company, between 2009 and 2012 on an innovation project called Textiles for Textiles -T4T to develop an industrial automated sorting machine with NIR technology and not achieving the expected outcomes, we decided to ask Valvan Baling Systems to join us in this endeavour and develop a solution to these issues.

Valvan has been developing, building and testing its own textile database and analysis software to enable the sorting application, under the brand name Fibersort, for several years now. This technology offers us the solution to find an alternative, high-value destination for our waste. In 2016, Valvan Baling Systems and ourselves, together with four other partners (Circle Economy, Leger des Heils ReShare, Procotex Corporation and Worn Again Technologies), have received funding support from the European Commission INTERREG NWE programme to optimise, validate and launch the FIBERSORT technology in the global market. On the 14th of March 2018, at Wieland Textiles, the consortium was able to present the Fibersort technology for the first time at a Demo Day. This year, on March 12th we will present the industry with the optimised version of the Fibersort, proving the potential and addressing the remaining challenges of automated sorting of post-consumer textiles, based on reusing post-consumer textile content in new garments. A real circular process and a solution for low quality textile waste.”

Hans Bon, Director, Wieland Textiles & Smart Fibersorting

Introduction

In Europe we are facing a growing mountain of used textiles. The accelerating consumption and disposal practices cause textiles entering the market to reach their end-of-use rapidly. In North-West Europe (NWE) alone, research shows that around 4,700 kilo tonnes of post-consumer textile (PCT) waste is generated every year. Still, only around 30% of PCT in NWE is collected separately while the rest is lost in household waste. In the best-case scenario, these textiles are sold in the second-hand market both locally and internationally. In NWE this average of rewearable textiles is around 64% of collected textiles. The remaining 36% is considered non-rewearable textiles due to their unsuitability for the second-hand market or the market saturation that second-hand clothing is currently facing. Almost all of these textiles are currently being downcycled, incinerated or landfilled while less than 1% of all textiles produced are currently recycled into new ones.3

Automated sorting technologies could enable the industry to turn non-rewearable textiles

that currently have no other destination than downcycling, landfill or incineration into

valuable feedstock for high-value recycling. One of these technologies is the Fibersort,

a Near Infrared (NIR) based technology able to categorise textiles based on their fibre

composition, structure and colour. While the technology is promising, identified sociocultural, physical, economic and regulatory barriers must first be overcome to ensure its successful implementation. In May 2019, the Fibersort Interreg NWE project published an overview of these potential barriers for the implementation of Fibersort technology for

collectors and sorters. This overview reflected macro trends in textiles, and identified

their implications for the importance, fit and potential of the Fibersort technology.

This report is the final publication of the Fibersort Interreg NWE project. As such, it

explores the critical success factors to address these key barriers (socio-cultural, physical,

economic) for an effective market uptake of recycled PCT and automated sorting

technologies, such as the Fibersort, in the long term in North-West Europe. The research

builds on interviews with industry stakeholders as well as publicly available data and

previous project research. At the end of the report, recommendations are formulated for

stakeholder groups across the value chain (collectors, sorters, recyclers, manufacturers,

brands and policymakers) to address the barriers outlined.

The Fibersort Journey

The Fibersort technology has been under development throughout the last decade. The

Fibersort Interreg NWE project (2016-2020) has allowed for it to be optimised and validated

for commercialisation. In the next pages of this report, you will discover the improvements

and updates made to the technology since the start of the project.

After this long journey, the partners that initiated the concept and development of this

innovation, Smart Fibersorting and Valvan Baling Systems, reflect on the road travelled

as well as the one that still remains ahead to ensure the successful implementation of the

technology in the long-term.

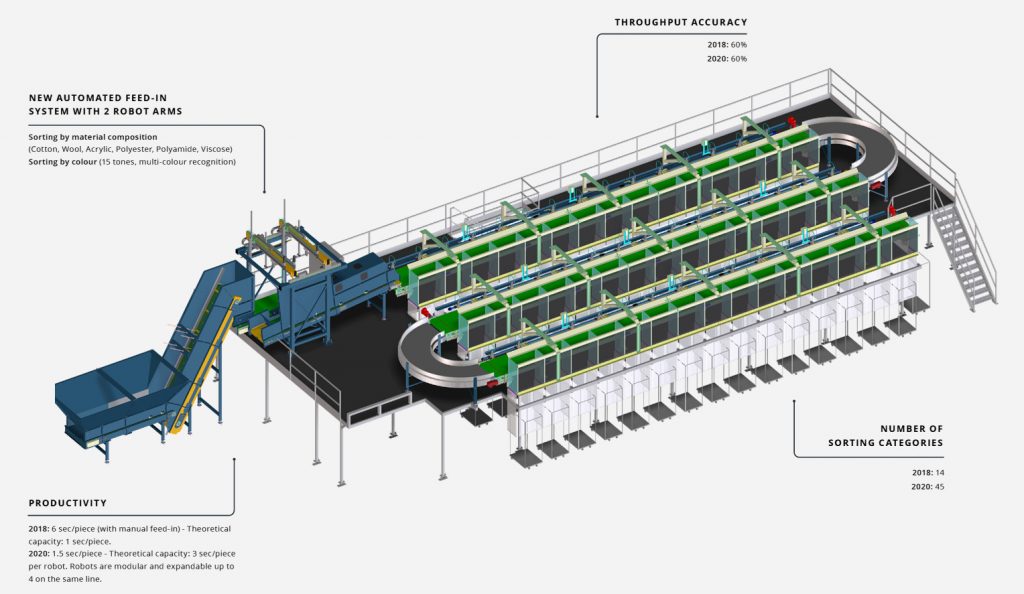

“Throughout the Fibersort NWE Interreg project we have learned a lot, made a lot of mistakes and developed the machine further. Today I am happy to say that the Fibersort technology is working very well. As a company specialised in developing machinery for making bales and sorting textiles, Valvan has had the responsibility throughout the project to produce the technology of the machine and ensure that it

is accurately sorting on fibre composition and colour.Further, we started the project with a manual feed-in system which we were now able to update to an automated feed-in system powered by robot arms that has enabled the machine to improve its productivity levels.

Nevertheless, sorting textiles in an automated manner is not an easy endeavour. After all of these years, we can assure that we have developed a complex technology that caters to a wide variety of textiles that come in multiple shapes, colours, compositions and material blends. In this regard, continuous improvement will be constantly required and we are determined to continue the journey to make the Fibersort better and better each day.”

Maurits Vandeputte, Project Engineer, Valvan Baling Systems

The Fibersort Today

The Fibersort is an automated sorting technology that enables the categorisation of textiles according to their fibre composition and colour. Based on NIR technology, the machine is able to provide accurate and reliable feedstock to textile-to-textile recyclers.

(Courtesy: Fibershot Working Group and Producer Network)