Pili Inc.: Biofabricator of living colors (made in microbes)

|

Pili is well on its way to becoming the world leader in bio-based dyes by multiplying industrial partnerships with application specialists in the textiles, inks, paints and plastics sectors.

Pili, a leader in the development of renewable colors, was awarded a grant of more than €400,000 for its Waste2BioComp project within the Horizon Europe program. This collaborative project bringing together 12 European partners (France, Germany, Italy, Portugal, Spain) aims to transform organic waste into sustainable and biosourced components for the textile, packaging and footwear industries.

Demonstrating the relevance of these processes on a pilot scale will pave the way for large-scale industrialization with a significant impact on reducing the use of fossil materials and CO2 emissions in many value chains with high environmental footprints such as packaging or clothing.

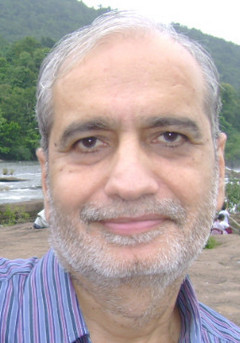

Pascal Simonney

Pascal Simonney, Chief Financial Officer of Pili declares : “This European project obtained on such a demanding program such as Horizon Europe demonstrates the relevance and the momentum for an industrial scale-up of our first pigment. It confirms the effectiveness of a dynamic and multidisciplinary team well supported by a network of recognized experts in biotechnology and industrial chemistry. This is a key milestone for the incredible industrial ramp-up that is shaping up in bio-based inks and textile dyes.”

Pili is strengthening its ecosystem of application partners, particularly in inks and textile printing. Recent tests carried out under semi-industrial conditions in the denim industry have demonstrated that the performance of the first Pili product is identical to that of conventional petro-based products. In order to increase its production and product development capabilities on an industrial scale, Pili is launching the construction of a pilot unit in the south of France this summer and is preparing the construction of a demonstration unit planned for next year. This investment will allow the establishment of a production tool generating the first million euros of turnover for the company.

Marie-Sarah Adenis, designer and biologist and one of the co-founders, explains: Marie-Sarah Adenis, designer and biologist and one of the co-founders, explains:

“It’s simple, we teach bacteria to make colored molecules thanks to their enzymes. We know that enzymes are catalysts for chemical reactions. Enzymes are like workers working on an assembly line: each has its own mission, for example adding or removing a group of atoms. From their coordinated reactions emerges a new molecule which will possess the qualities of color and the physico-chemical properties desired to dye various textile fibres. In short: through its molecular manipulations, Pili manufactures organic pigments.” |

Since its inception, Pili’s mission has been to decarbonize the color industry. By recovering local renewable resources (non-food biomass present on French territory – straw, oils, molasses, biomass from industrial waste), these processes will make it possible to significantly reduce CO2 emissions from industry on a planetary scale as well as the use of fossil materials (oil, coal). They will also make it possible to reduce the strong dependence of many industrial sectors on imports outside the UE while creating qualified jobs in the territory. In 2023, Pili will enter the marketing and industrialization phase for its first textile coloring product : indigo.

About Pili

Pili is the leader in the development of biobased dyes and pigments. Its unique processes combining fermentation and sustainable chemistry allow the production of colors that are both efficient and ecological.

Its technology has the potential to free itself from polluting petroleum and chemicals involved in the production of colors in the textile, plastics, paints and inks sectors.

Founded in 2015, Pili is based at Toulouse White Biotechnology (TWB) and the Conservatoire National des Arts et Métiers (CNAM) in Paris. Now employing thirty people, the company has invested more than 13 million euros since its creation thanks to public and private financiers such as BPI France, SOSV, Elaia as well as many individual investors.