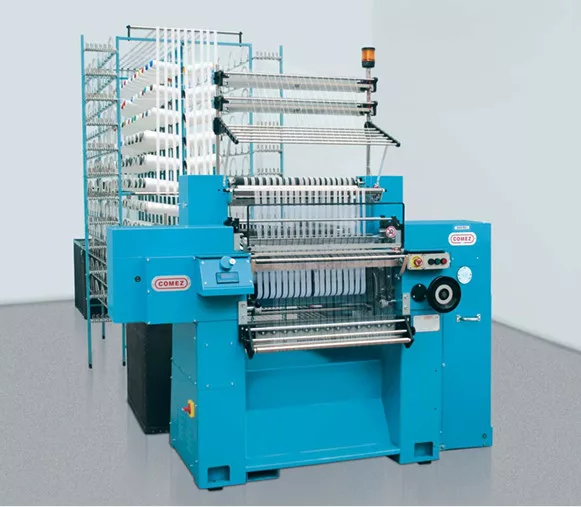

COMEZ 609/B8

COMEZ 609/B8

COMEZ 609/B8

High efficiency crochet knitting machine for the production of a wide range of elastic and non-elastic narrow fabrics.

It is built with a modular system that allows application in an easy way of a great number of devices that only COMEZ offers, completing the basic machine and giving it a very high versatility.

The versatility comprises:

- a wide range of products that can be made, including laces, bands and ribbons, both elastic and non-elastic

- multiple pattern possibilities, using the 8 weft bars and the chain links extensions

- several gauges available, allowing many different types of article.

In designing this machine, particular importance has been given to the easiness of use and accessibility, so that all operations for regulations and maintenance are facilitated.

The machine is fitted with 8 weft bars controlled by chain links.

As an alternative, two bars can be driven by the weft device, controlled by eccentrics and 2 levers, allowing for steady weft movements of up to 50 mm.

The chain is composed of links with involute profile, which guarantee high operating speeds, reduce the noise emission levels and limit considerably the vibrations of the machine.

The particular features of the weft bars (protected by international patent) eliminate any vibrations of the thread-guides and avoid breakages of needles and of thread-guide tubes.

By means of the SET150/600 and SET/2-290 devices, weft movements of up to 150 or 290 mm can be effected, adapting the machine speed to the movement.

The supplementary warp tube bar BPO/S-600F (on request) is an important feature of this machine: it can be used as second warp bar, enabling the semi lock-stitch effect to be achieved.

On request, the machine can be fitted with a colour touch screen controller (DCF-C-M/C) which allows to:

- vary the machine speed

- visualize the machine speed in RPM

- set the sensitivity (time of permanence of the drop wires on the stop-stems) of weft and warp stop motions separately

- plan a production (pick counter or production unit [m, kg, etc.])

- visualize the production for shift

- visualize automatically the reason of the machine stoppages

- visualize the machine time of running and stopping in hh:mm (hour counter).

The DCF-C-M/C device requires the machine to be equipped with a special electrical panel, in place of the standard one: for this reason the device must be requested when ordering the machine, since its assembly must be carried out at the COMEZ plant.

The Machine is Equipped With:

- 3-roller feeder for elastic threads

- heddle bar for elastic threads

- electronic speed variator INVERTER

- pilot lamp

- work area safety device

- chain links extension for up to 48 repeats

- automatic tensioner for warp threads

- weft device, controlled by eccentrics and 2 levers

- digital revolution counter

- automatic stop motions for incorrect product winding onto the rollers

- automatic stop motions for thread breaks or empty cones

- standard supply package of consumables and accessories

Technical Specifications

| gauge | 10 12 14 15 20 24 n.p.i. 6 8 n.p.cm |

| number of needle grooves on needle bed | 240 279 340 360 480 560 360 480 |

| working width | 600 mm |

| number of weft bars | 8 controlled by chain links |

| needle type | bearded needles |

| stitch density | 5 – 25 stitches/cm |

| chain links ratio | 12 – 48 |

| electrical supply mains | 200 – 240 / 380 – 440 V, AC, 3-phase + earth |

| main motor power | 1.5 kW |

| installed power | 1.7 kVA |

| noise emission | 70 dB (A) |

| machine net weight | 570 kg |

End Product Samples

Contact details

Jakob Müller (India) Pvt. Ltd.

Plot No. 27, 4th Main, Bommasandra Industrial Area,

Bangalore 560 099, India Tel. +91 80 278 35 126 / 128

Email: [email protected] Website: www.mueller-frick.com

Comez Sales Area Manager: Alessandro Barchielli