Category: Executive Pages

ITMF’s International Production Cost Comparison (IPCC) in the Textile Industry

ITMF’s International Production Cost Comparison (IPCC) is designed to trace the implications of the growing capital intensity in the primary textile i [...]

NatureTech Enviro Protection Ltd.

"I have inherited a beautiful world which was inherited by my parents by their own. There is so much beauty in the world and it cannot be lost bec [...]

Naturetech Enviro Protection Ltd. Offering Cleartec Technology for Textile Wastewater Treatment

Naturetech Enviro Protection Ltd., a leading Surat-based environmental solution provider, has been offering an array of latest technologies dedicated [...]

Textile & Allied: Industrial Licences Issued in November 2018

Textile & Allied: Industrial Licences Issued in November 2018 [...]

“Smart LeucoIndigo”: Electricity Instead Of Chemicals

Smart-Indigo™: High sustainability; Reduced health hazards; Savings in wastewater treatment and energy; Better colour consistency and performa [...]

Adaptive Textile Façade at Aachen Reduces Nitrogen Oxide Pollution & Urban Heat

The adaptive textile façade green.fACade, developed from Aachen researchers, is installed in front of a building like a second skin and can permanent [...]

Zoroguard-ZP: Antifungal and Antibacterial Agent from Sarex

Mould, mildew, fungus, yeast, and bacteria (microorganisms) are part and parcel of our everyday lives. Thousand of species of microorganisms are foun [...]

Detergents, Cosmetics, and Clothes Producing Everyday Products with Fungi

Most detergents, cosmetics, and clothes, to name just a few products, are manufactured using petroleum, making such everyday items anything but eco- [...]

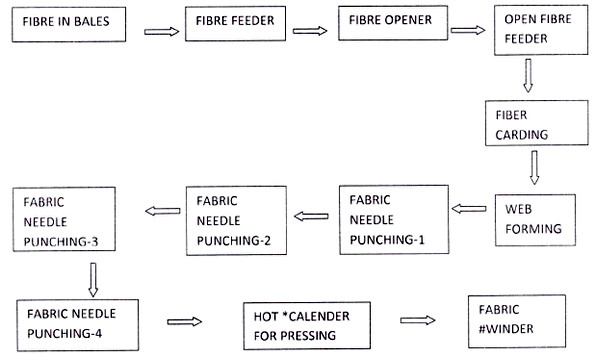

Non-woven Fabric is NOT a Textile Item

The Excise & Taxation Commissioner, Haryana, Panchkula, on March 22, issued a clarification in the case of M/s Jasch Plastics India Ltd., Kundli, [...]

Company Profile: Applied Laser Engineering Ltd.

ALE has been involved in the manufacture of Functional Topographic surfaces for more than 25 years. This privately owned, company has provided leaders [...]