Tip Switch Vacuum: The new standard

Tip Switch Vacuum: The new standard

The flagship brand of UV printing technologies, swissQprint, now offers Type Switch Vacuum in all flatbed printing machines reflecting its high precision and reliability to Swiss engineering. SwissQprint’s third generation Oryx 3, Impala 3 and Nyala 3 UV printers are all equipped with this vacuum system, which facilitates the printing job and increases the performance above average. The swissQprint vacuum system has always been a top performer; now it has grown yet more efficient and easier to use.

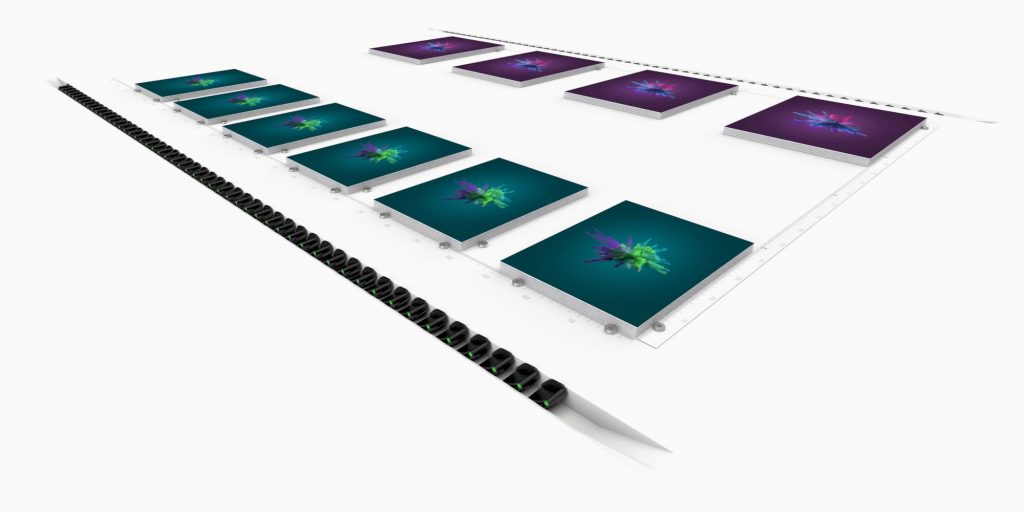

Tip Switch Vacuum makes working a whole lot more light-handed – literally, because you have full fingertip control of the finely segmented vacuum table. Opening or shutting off up to 256 vacuum channels is lightning fast and super easy, not least in the gaps between media such as multiple copies or dual rolls. Tip Switch Vacuum sets new standards in user friendliness, performance and efficiency. See for yourself:

swissQprint large format printers have been certified for their very high energy efficiency since 2018 (ISO 20690:2018). One contributor to this is the vacuum system with its underpressure-controlled pumps that only operate at full speed until the required negative pressure has developed. This also makes for a pleasantly quiet system.

Tip Switch Vacuum For effortless vacuum control

Setting the print bed vacuum is child’s play with Nyala. Using the Tip Switch vacuum, each of the 256 vacuum segments is switched on and off in no time at all with just the touch of a finger, no additional masking required.

Run it over the vacuum tip switches across the print bed width and open all of the 256 vacuum channels in just a few seconds. Once the material is loaded, do the same to shut off the segments below the uncovered surfaces:

With series of boards, between individual media.

With series of boards, between individual media.

With dual rolls, also in the gap between them.

With dual rolls, also in the gap between them.

When printing in tandem, in the front zone as well as in the rear.

When printing in tandem, in the front zone as well as in the rear.

Masking and taping? That’s unnecessary as you can switch the vacuum on or off in very small segments to avoid leaks. This allows the vacuum to develop its full force exactly where needed and securely hold down the substrate. To help you keep track, each switch has a green and red indicator to show its open or closed status.

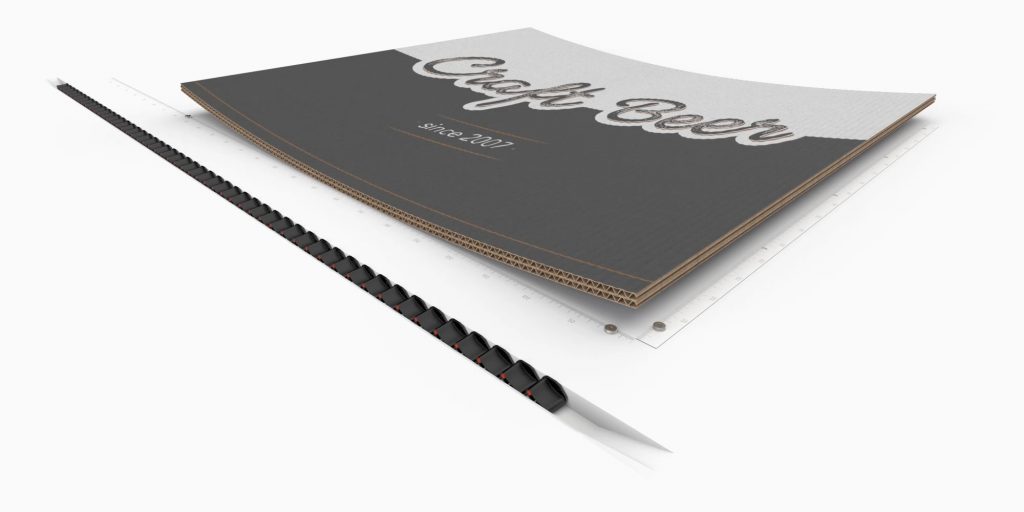

The vacuum also keeps notoriously unruly media in check.

The vacuum also keeps notoriously unruly media in check.

Vacuum intensity is freely adjustable via the output software. Moreover, the vacuum automatically reduces once there is sufficient underpressure or while roll material is being advanced. The results: a quiet working environment, minimum power consumption (ISO-certified) and precision feeding.

Tip Switch vacuum is the subject of a patent application.