Pilling is a major problem in Textile and Apparel manufacturing. Pilling is defined as the tendency of fibers to work loose from a surface and form balled or matted particles that remain attached to the surface of the fabric. For the end consumer, it affects fabric aesthetics and comfort.

For the manufacturer, fabric pilling is a headache that affects the appearance and wearability of finished apparels. It turns out that pilling is a complex phenomenon comprised of multiple stages that progressively accelerate the rate of fiber removal from the yarn structure, thus shortening the life span of garments and other textile products. Pilling is particularly problematic for knitted fabrics. At the same time, knitted fabrics have several advantages over woven fabrics, such as higher production rates, lower production costs and softer fabric structures. Still, the pilling problem that results from the slack fabric structure remains a significant objection. Essentially there are a number of methods to reduce pilling in commercial use. One approach is to apply surface active agents, like a polymeric coating that binds fibers to the fabric surface. These are often friction reducing lubricants, such as acrylic copolymers. Shearing and Singeing are common methods used to produce a clean, smooth surface on fabrics. Singeing, in particular has the very real potential to scorch the fabric surface. The down side of surface active agents include a reduction in hydrophilicity and the gradual loss of the agent after a few washes, which eventually makes fabrics harsh and fuzzy.

Enzymatic removal of fuzz is carried out under milder conditions and is absolutely safe, efficient and permanent. Cellulose enzymes give fabrics a clear, even surface appearance. They reduce the tendency to pill and improve softness, especially when compared to traditional softeners. More importantly, they accomplish this without polluting the environment. As a result, Cellulases are increasingly being applied to textile finishing. They are widely used to remove fibrils and fuzz fibers from cotton fabrics, or to produce a “stone-washed” look in denim garments. However, there is some loss of tensile strength with cellulase enzymes.

Advanced Enzyme Technologies offer Addscour LPP and Addscour PCLP – Bio-scouring enzymes for complete removal of pectin, oil, wax & dirt from raw cotton, under caustic-free or low caustic conditions during the scouring process. SEBrite is a very unique product used for biopolishing of cotton fabrics.

What we normally call Cellulase, is actually a complex of cellulase enzymes – a mixture of three major groups : endoglucanase (EG), cellobiohydrolase (CBH) and cellobiase. Endoglucanases mainly hydrolyze internal bonds in the cellulose polymer, producing new chain ends and thereby causing a considerable decrease in cellulose DP. CBH is needed for complete hydrolysis of crystalline region producing dimers of glucose. CBH enzymes are exoglucanases, which initiate hydrolysis at the chain ends. For textile processing, the most important cellulase enzymes are predominantly EG, CBH.

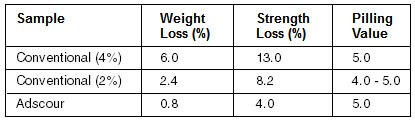

A test comparing 2% caustic scoured, 4% caustic scoured and Bioscoured cotton using single jersey knitted fabric was conducted by carrying out the processing in a Soft flow Machine, all the samples were bleached with H2O2. The test results are given below.

Bioscoured cotton showed high pilling resistance , lower weight loss and less strength loss, i.e. more pilling resistance and greater value. This result may due to the untouched cellulose structure compared to a conventional chemical boil. While the 4% caustic boiling bath showed high pilling resistance, when studied in detail, it showed the fibrils formed in high caustic treatment are so weak that they are cut off by the mechanical action of the pilling tester. Here weight loss is significantly greater.

Conclusion :

Cellulase Enzymes are Important tools in the Cotton textile Industry. They provide an Economical and Environmental friendly way to treat cotton and its blends. The potential issue of loss in tensile strength can be reduced by using proper combination of EG & CBH enzymes as demonstrated in Advanced Enzyme Technologies Ltd Product, SEBrite. Cost effective and eco-friendly biopolishing results can be achieved by proper application with right blending of Cellulase enzymes after Bioscouring.

For more information on enzymes offered by Advanced Enzyme Technologies, please contact :

COMET

402, Satyam Mall, Opp. Mansi Tower,

Jodhpur Bodakdev Road, Satellite, Ahmedabad – 380015

Phone : (079) 30151719/24 Fax : (079) 30021605

Email : [email protected]

(This article is sponsored by COMET. The content is reproduced from a presentation made at the Seminar organised by COMET’s principals M/s Advanced Enzyme Technologies Ltd. (SEB Group, USA)