The Machinery Used in Hemp Processing

The Machinery Used in Hemp Processing

Processing hemp is not a “one-size-fits-all” sort of endeavor, as it involves precise measurements and many trials to get the hemp to behave in the fashion needed for user end-products. Plant fibers are truly another species of textiles. People are excited about and investing in the possibilities and potential growing hemp can bring to our fiber systems: hemp farmers and yarn makers have already started getting acquainted with hemp.

The final samples range from a wood-like material created from shredded hemp fiber to long, fine strands of hemp for textile goods that can be blended with other natural fibers to add strength, comfort, and the ability to resist abrasion as well as mold/rotting. It’s the unique ability of hemp to shape-shift to meet users’ needs. This helps in figuring out how to fine tune equipment used for processing hemp. Creating consistent hemp fiber that can match the needs of where they are headed next is their biggest challenge, and one that processors are actively investigating.

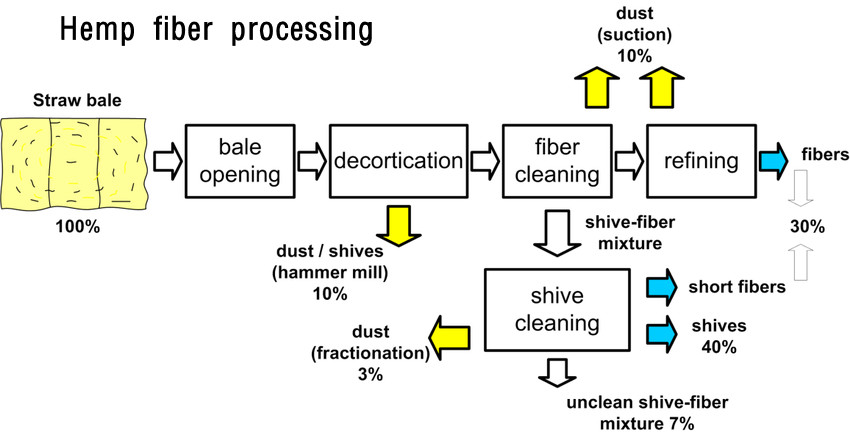

Hemp goes through a similar process to linen, called retting, using water to break down or rot the cellular tissues of the stem allowing the bundles of bast-fibers to separate from the stem of the plant. This usually happens right after harvesting the hemp in fields where the hemp is left to ret in the fields. This dependence on the natural process of retting makes for bales of hemp coming in at different stages in the process, with some bales having been retted more than others. Contaminants in the bales contribute to the complex job of getting the kind of hemp product that fiber mills are eager to work with.

The largest machine, taking up half the building, is loud, with pipes leading in multiple directions. It takes the straw-like hemp and spits out, almost as if by some sort of magic, a fine, fluffy fiber that loosely resembles the “straw” going in, but has taken on a totally different form.

[smartslider3 slider=”5″]

(Courtesy: Maddy Bartsch, Fibershed)

Hemp finds end uses for the fiber, from clothing to building materials and everything in between. There’s also a lot of other natural and reliable building materials that can be used too such as timber, what’s even better now a days is materials get placed into storage like a timber rack or other storage systems, this way the building materials don’t get effected by weather or other forms of erosion. There is an endless supply of uses for fiber and it can be kept as a reliable source and material due to these protection measures being taken.

There is also an opportunity for larger retailers looking to make inventive blends of hemp and Climate Beneficial Wool. There also exist business possibilities for large production mills to offer small fiber mills the potential to create farm yarns that combine the beauty of protein fibers and cellulose fibers all grown within the same region.

Processing Hemp from the field to textile fibre

The future is bright for hemp products and what this natural fiber can do for the local fiber systems thanks to the small-yet-active hemp community across the US.