A Zero Liquid Discharge (ZLD) system is a combination of technologies that work together to minimize wastewater as much as technically and economically practical, often resulting in a concentrated solid product and high-quality clean water for re-use or environmental discharge. Integrating a ZLD system into your process increases resiliency by reducing both cost and risk. ZLD works to secure control over your water source and waste disposal reducing the influence of factors outside of your control. In many applications, ZLD can enable the creation of value products or energy from waste, significantly improving project economics.

What is Zero Liquid Discharge?

The goal of any Zero Liquid Discharge system is to minimize liquid waste from a system or a process, and turn it into clean water that can be reused, along with solids that can either be used, sold, or safely disposed of. Most industrial processes will use freshwater at some point, which will often result in wastewater. Here’s where a ZLD system comes in. The wastewater is pumped into this system, where it goes through a process which can involve heating, separation, decanting and evaporation, depending on the system used. From this there will be two end products – treated water which can be reused, and solids which can be sold, used in the industrial process, or disposed of, depending on the nature of the solid and the quality.

Why is this important?

It’s essential for businesses to try and limit waste as much as possible, both for the sake of the environment and for the sake of costs and profit margins. It’s also a requirement, depending on where you are in the world. Many governments have introduced strict regulations around discharge, and there are water reuse requirements in certain regions too. Eliminating waste and becoming more sustainable is hugely important, and ZLD technology can help with this, whilst also making businesses more profitable in the long-run.

Key benefits

There are three key benefits to implementing a ZLD system into your industrial process:

- Minimize your waste: An efficient ZLD system will minimize, or even eliminate wastewater completely. This can have a major impact on your sustainability.

- Re-use water: The water treated in the ZLD system can often be reused in the industrial process that required fresh water in the first place. As you don’t need as much water, your costs decrease as well as your environmental impact.

- Create value.: The solids produce can vary, but some may be salt that can be resold, or chemicals that can be put to use in the initial process. This means even less actual waste is produced, as even the solid substances can be a benefit to your business.

How does it work?

Alfa Laval ZLD systems work with a combination of thermal solutions and separation technology, with the AlfaFlash evaporator at the core of the set up. This is what makes our ZLD solution class-leading, but let’s take a look at how the process works step-by-step.

Step 1 – Water is fed into the evaporator exchanger:

Fluid is heated under pressure so that it doesn’t boil in the evaporator heat exchanger, and the entrance to the exchanger ensures an even flow of fluid over the entire plate. Fluid is heated under pressure as it moves up the channels.

Step 2 – Fluid is pushed through the Flash Orifice:

At the point, back pressure is created on the fluid to prevent boiling inside the heat exchanger. As the heated fluids pass through, the pressure drops which leads to some of the fluid flashing to steam.

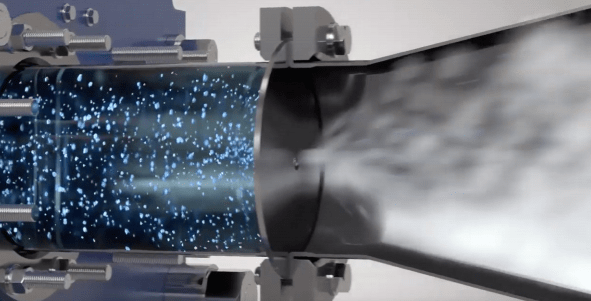

Step 3 – Cyclone separator:

The mixture is now essentially in two phases – fluid and vapour. The stream is entering the cyclone separator, where centrifugal forces improve the vapour liquid separation. Vapour rises into space above the circulating fluid, where mists and fine droplets are removed. A vortex breaker at the base of the separator smooths the flow of the remaining fluid into the recirculation pump.

Step 4 – Recirculation pump:

The concentrated fluid is then transported through the AlfaFlash system by the recirculation pump, where pushed through to the decanter.

Step 5 – Decanter:

Now the fluid is put through the decanter, where water is separated from solids. This results in minimum levels of waste, and maximum water recovery. The solids can be used, sold, or disposed of, and the water can be pumped away to be used once again in the main industrial process. The types of crystals generated from waste water are seldom uniform and large. The slurry consists of particles with mixed sizes, where the smallest sized particles are especially hard to separate. Alfa Laval decanter centrifuges are designed to handle a wide range of solid particles with diameters from 5 mm to a few microns. The technology is based on centrifugal separation thereby using g-force to improve separation efficiency. The settling velocity of a crystal is directly proportional to the g-force. The decanter centrifuge generates around 3000 g which dramatically increases settling speed, and also improves the efficiency of the really small particles which settle very slowly in static separation. The decanter centrifuge technology is not sensitive to smaller particles as it does not have a mesh. Other technologies such as filters have the risk

Risks in ZLD applications:

The primary risks in ZLD applications include fouling, corrosion, and uncertain or variable physical properties. AlfaFlash is extremely effective in dealing with the risks associated with normal ZLD processes:

- Fouling:

Fouling is the unwanted accumulation of solids on evaporator heat exchanger surfaces, and can drastically reduce the system performance, or even result in failure to meet required performance levels which can be costly. A key factor in keeping fouling to a minimum is through high shear stress. Fluids moving along a heat exchanger surface create shear stress at the surface, and sufficient shear stress reduces attachment and increases removal of solids from the surface, resulting in a self-cleaning effect. The higher the shear stress, the more effective the cleaning. The Alfa Laval solution can offer higher shear stress due to the corrugated design of the heat exchange surfaces. This creates a lot of disturbance in the flow of fluid, which increases the friction factor, which in turn increases the shear stress. The result is that the AlfaFlash system has typically 5-10 times higher shear stress on the surface compared with a forced circulation shell & tube system, even though the actual channel velocity is often less than half. In one of the most comprehensive tests, carried out by Heat Transfer Research Incorporated, this resulted in a fouling reduction of 50-70% when operating at a typical industrial velocity. This high shear stress also helps break down major debris, ensuring no large particles can cause blockages, whilst preventing smaller particles like crystals from going too large. Typically, the size of the particles circulating are smaller than 0.1 mm, and the gaps between plates are between 5 and 8 mm. This means the gaps are 50 to 80 times larger than the biggest particles, ensuring a clean, consistent flow with no risk of blockage.

- Corrosion:

ZLD evaporators often process highly corrosive fluids, and deterioration by corrosion can lead to failures that require long periods of downtime are required costly equipment replacement. The corrosion potential is usually assessed on the basis of chloride content, pH, and temperature. Chlorides can create devasting corrosive effects on many materials, especially in high temperature, low pH environments and chloride crevice corrosion is one of the most common reasons why metal heat exchangers, pipework, and vessels fail in ZLD applications. The corrosion resistance of stainless steels arises from a passive oxide film that forms on the surface of the steel. Under certain conditions, the passive state can be broken down, resulting in corrosive attack. The oxide film on titanium is significantly more stable than that of stainless-steel alloys. The AlfaFlash plate and frame heat exchangers can be cost effectively manufactured from titanium compared with shell and tube alternatives which are usually manufactured from stainless alloys. The corrosion resistance of titanium can be 10 to 20 times greater than corrosion resistance stainless alloys such as duplex and super duplex, making it an ideal material for ZLD applications.

- Uncertain physical properties:

ZLD often involves the concentration of solutions with a wide range of components and the composition is often highly variable. After concentrating these solutions, it can be difficult to accurately predict their physical properties, especially to high concentration factors and slurries. Physical properties such as density, viscosity, and boiling point elevation have a significant impact on the design of the heat exchangers in ZLD systems. One of the key advantages of Alfa Laval plate and frame technology is the adaptability and flexibility. After installation, the heat exchangers can easily be modified by adding or removing or replacing plates. This potential for modification allows the system to adapt if physical properties are different than originally expected, or if they have changed from original conditions. This type of modification is not possible with shell and tube heat exchanges without replacing the entire the heat exchanger. Ensuring the system is designed for the correct boiling point elevation is also critical. If the actual temperature approach is less than the design specified, more heat exchanger area is required to meet the desired capacity. Adding additional area with plate and frame heat exchangers is easy, inexpensive, and can be done at any time.

Summary

Investing in ZLD system benefits business, and the environment. By cutting down on waste and improving sustainability, we can make a real difference to the way your industrial process works and how much impact it has. It also ensures that we’re prepared for any wastage regulations that may be introduced in our region. Everything about our ZLD solution is designed to be cost efficient too, with low investment, installation and operational costs.